Description

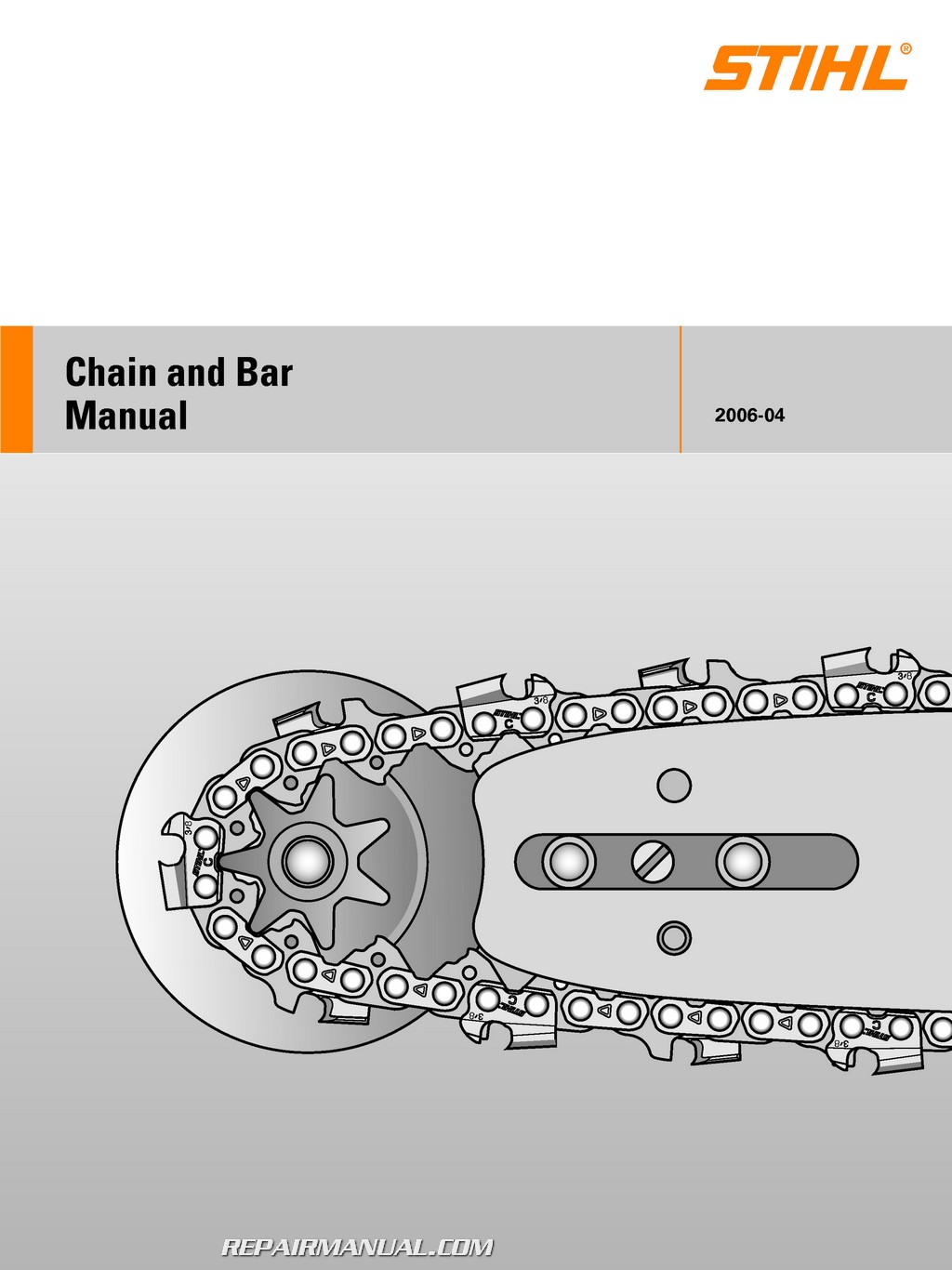

This 62 page, Stihl Chain and Bar Manual is intended as a guide to selection of the correct cutting attachment for a specific application as well as to its proper use and maintenance. It is important that you read, fully understand and observe the instructions in the chain saw manual. Non-observance of the instruction manual may result in serious or fatal injury. Special safety precautions must be observed to reduce the risk of personal injury when working with a chain saw because of the very high chain speed and very sharp cutters.

Stihl Chain and Bar Manual Table of Contents

OILOMATIC

Saw Chain

Introduction

Construction

Criteria for Selection

Chain Pitch

Drive Link Gauge

Chain Types

Basic Types

Versions

System

of Designations

Part Number and

Marketing Number

RAPID Chain

RAPID Micro (RM)

RAPID Micro C (RMC)

RAPID Micro C3

(RMC3)

RAPID Micro 2 (RM2)

RAPID Micro

Harvester S (RMHS)

RAPID Micro

Harvester (RMH)

RAPID Super (RS)

RAPID Super

Klassik (RSK)

RAPID Super C (RSC)

RAPID Super C3

(RSC3)

RAPID Super LK

(RSLK)

Full-Skip and

Semi-Skip Chains

RAPID Duro (RD)

RAPID Duro Rescue

(RDR)

PICCO Chain

PICCO Micro (PM)

PICCO Micro 1 (PM1)

Picco Micro C3

(PMC3)

PICCO Micro

Narrow (PMN)

Low Kickback Chains

How the OILOMATIC

Chain Operates

Geometry

of the Cutter

Clearance Angle

of the Top Plate

Clearance Angle

of the Side Plate

Top Plate

Cutting Angle

Filing Angle

Depth Gauge Setting

Chip Removal

Use of Saw Chain

Mounting

the Saw Chain

Chain Tension

Breaking In

the Saw Chain

Chain Lubrication

Checking Chain

Lubrication

STIHL OILOMATIC

Principle

Chain Lubricating Oil

Sharpening

the Saw Chain

Preparing

the Saw Chain

File and File Holder

Checking

Depth Gauge

Filing Tools

Sharpeners

Checking Angles

Sharpening Errors

Repairing Saw Chain

STIHL Rivet Spinners

and Chain Breakers

Replacing

Chain Links

Ematic Guide Bars

Criteria for Selection

Bar Tail

Groove Width

Part Number

Basic Types and

Versions

DUROMATIC E

ROLLOMATIC

Guide Bars

ROLLOMATIC E

ROLLOMATIC E Light

ROLLOMATIC Mini

ROLLOMATIC ES

STIHL Carving Bar

STIHL Ematic

Principle

STIHL Ematic System

Maintenance

Repairing

Bar Rails, Removing

Burrs

Straightening

Opening the Groove

Closing the Groove

Replacing the Nose

Sprocket

Replacing the

Bar Nose

Chain Sprockets

Spur Sprocket

Rim Sprocket

Checking the Chain

Sprocket

Cutting Attachment

Conditions –

Causes. Remedies

Saw Chain

Drive Links

Cutters and

Tie Straps

Depth Gauges

Incorrect Sharpening

Angles

Guide Bars

Chain Sprockets

SKU: OM-TY20760

SKU: OM-TY20760 SKU: OM-GA10224-I2

SKU: OM-GA10224-I2 SKU: TILL-S-581

SKU: TILL-S-581