Description

This 270 page, Allis Chalmers H3 HD3 Service Manual is a high quality reproduction of the original out of print manual. This manual provides detailed service information, step-by-step repair instruction and maintenance specifications for the Allis Chalmers H3 & HD3 tractors.

Table of Contents

149 Gasoline Engine (H-3 Crawler Tractor)

DISTRIBUTOR REMOVAL AND ASSEMBLY

ENGINE REMOVAL AND ASSEMBLY

Camshaft

Connecting Rod Beatings

Connecting Rods anil Pistons

Crankshaft and Main 8carings

Cylinder Head

Flywheel

Oil Pump

Oil Sump

Rocker Arm and Shaft

Thermostat

Timing – Gear Cover

Water Pump

GOVERNOR

Adjustment

Removal

Operation

SPECIFICATIONS

Engine Specifications

Fits and Tolerances

149 Gas Prior to S’N 69b9

160 Gas S/N 6969 – 8694

160 Gas S/N 8604 and up

Torque Specifications

TIMING THE ENGINE

Distributor Timing

Front Crankshaft Timing

Flywheel Timing

Carburetor

ADJUSTMENT

ASSEMBLY

High Angle Carburetor

TSX 879/TSX 912

GENERAL PRINCIPLES OF OPERATION

Choke System

Float System

Idle System

Power Fuel Feed System

REMOVAL OF CARBURETOR

Diesel Engine (HD-3 Crawler Tractor)

ENGINE REMOVAL AND DISASSEMBLY

Camshaft

Connecting Rods

Crankshaft

Cylinder Head

Cylinder Liners

Flywheel

Oil Pressure Relief Valve

Oil Pump

Oil Sump

Rear Oil Seal and Adaptor Plate

Rocker Arm Shaft

Thermostat

Timing Gear and Cover

SPECIFICATIONS {D175 ENGINE)

Fits and Tolerances of New Parts

TROUBLESHOOTING

Air Intake System

Cooling System

Electrical System

Engine

Fuel System

Lubricating System

Fuel Injection Pump

AIR TIMING

AIR OR ENERGY CELL

DISASSEMBLY

DRIVE SHAFT (INJECTION PUMP)

GENERAL TESTS AND BENCH TESTS

INSTALLATION

FUEL SYSTEM

Construction and Operation

A Components

B Fuel Flow

C Charging and Discharging

(Delivery Valve Type Rotor)

D Delivery Valve Function

E Return Oil Circuit

F End Plate Operation

G Centrifugal Governor

PARTS INSPECTION

PRIMING PUMP

REASSEMBLY (STEPS 1 THRU 22)

TRANSFER PUMP (DISASSEMBLY)

Metering Valve

NOZZLE HOLDER AND NOZZLE

Electrical System

BATTERY

Charging

Maintenance and Service

Operation

Specifications

Testing

GENERATOR

Disassembly and Testing

Reassembly and polarizing

REGULATOR

Adjustment

Action (Load Checks!

Current Operation and Cut out Relay Action

Current Voltage Regulator Action ,

Electrical Check

STARTING MOTOR GAS AND DIESEL

Cranking Motor Tests

Disassembly

Operation

Reassembly

WIRING DIAGRAM

Diesel

Gas

Torque Housing And Shuttle Clutch

TORQUE HOUSING

ASSEMBLY AND ALIGNMENT PROCEDURE

ENGINE CLUTCH SHAFT

HOLLOW SHAFT W/GEARS

IDLER SHAFT AND GEARS

INTERMEDIATE SHAFT AND GEARS

PIVOT AXLE BRACKET AND BUMP STOP BRACKET ,

POWER TAKE OFF SHAFT (FRONT)

SHUTTLE CLUTCH

ASSEMBLY

LEVER ADJUSTMENT

POWER DIRECTOR

REMOVAL AND DISASSEMBLY

Transmission Assembly

GEAR SHAFT

Assembly and Removal

Cover

Forward and Reverse Transmission

4 Speed and Power Director

HOUSING

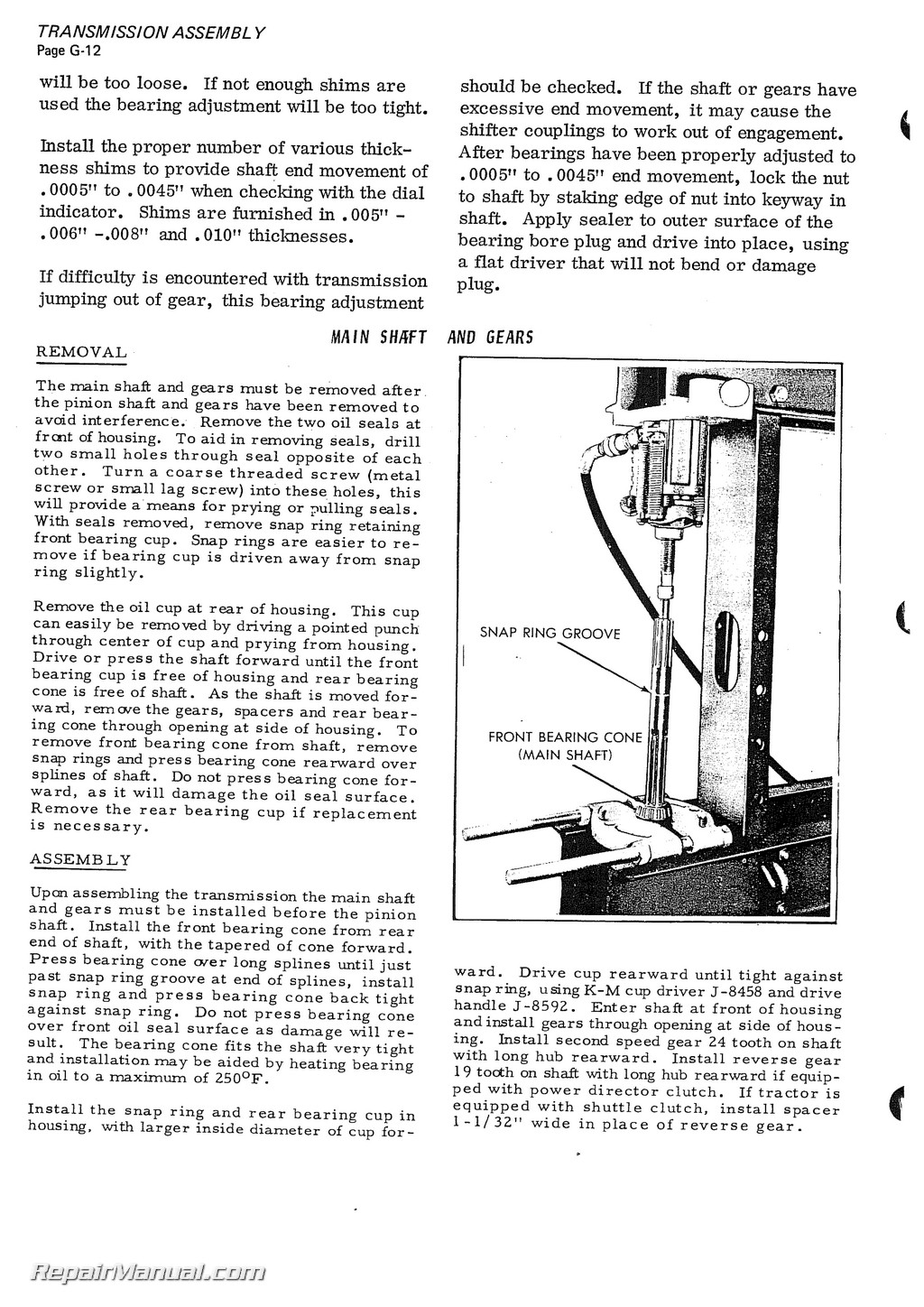

MAINSHAFT AND GEARS

POWER TAKE OFF

Driven Shaft

Idler Shaft and Gears

PINION SHAFT AND GEARS

REAR PTO – SHAFT OIL SEAL

REVERSE IDLER GEAR

STANDARD AND POWER DIRECTOR TRANSMISSION GEARS

Final Drive, Steering Clutches And Brakes

FINAL DRIVE ASSEMBLY

AXLE SHAFT REMOVAL AND ASSEMBLY

FINAL DRIVE ASSEMBLY – PRELOAD

HOUSING REMOVAL AND ASSEMBLY

OIL LEVEL CHECK

SPROCKET AND FINAL DRIVE

STEERING CLUTCHES

ASSEMBLY

CLUTCH RELEASE BEARING AND FORK

INSTALLATION METHOD

REMOVAL

BRAKES

ADJUSTMENT (BRAKE BANDS)

BRAKE LATCH

BRAKE LEVER

PLUG ASSEMBLY FOR STEERING CLUTCH HOUSING

Tracks And Undercarriage

FRONT IDLER (EFF w/H-3 – HD-3 S/N 8298)

LUBRICATION

SPROCKET

TRACK FRAME

TRACK AND UNDERCARRIAGE

Adjustment

Wear Gauge

Alignment

Dimensions

Idler Wear Pattern Gauge

Roller Frame

Removal

Support Rollers

Prior to S/N (8298)

Eff w/H-3 S/N (8298)

Tension Spring

Hydraulic Pump

DRIVE AND MOUNTING

Eff w/Tractor S/N 8694 and up

FLO RATING (2 STAGE PUMP)

GENERAL INFORMATION

IDENTIFICATION AND PUMP REFERENCE NUMBERS

PUMP

Inspection

Alignment

Bearings

Dimensions Inspection

Drive Shaft and Seals

Gears and Gear Plate

Rings (Sealing, Loading and Backup)

Wear Plate

SINGLE STAGE 11 5 GPM PUMP

Removal, Disassembly and Assembly

2 STAGE 11 5-6 GPM PUMP

Removal, Disassembly and Assembly

Seals (End Section)

2JDS2-L, 4JDS3-L and 4JDS2-L

Removal, Disassembly and Assembly

TYPICAL PERFORMANCE CURVES

2JDS2-L Pump

4JDS3-L Pump

IYDS6/IYID6-LB Pump

IYDS6/OYD6-LB Pump

Control Valve

1 OR 3 SPOOL CONTROL VALVE

3 SPOOL CONTROL VALVE

Assembly

Oil Flow (Float, Lift and Lower Pisition)

Relief Valve

Valve Spool (Plunger Removal)

ANTI-CAVITATION LINE

HYDRAULIC PRESSURE SETTING

INSTALLATION OF CONTROL VALVE

LOADER HYDRAULIC CIRCUIT

Circuit Relief Valve

Assembly

Checking and Adjustment

Disassembly

Operation

Maintenance (Hydraulic Relief Valve)

Hydraulic Cylinders (service Information)

1066 LOADER, 1003SCARIFIER AND ATTACHMENTS

(w/Threaded Piston)

Assembly

Removal and Disassembly

1080,1081 AND 1090 DOZER

(Lift, Angle and Hydraulic Till Cylinders)

Removal, Disassembly and Assembly