Description

This 210 page, Bobcat 970 G&D Skid Steer Factory Service Manual provides detailed service information, step-by-step repair instruction and maintenance specifications for Bobcat M-970 Loaders.

Table of Contents

Operation of Bobcat M-970 Loader

Loader Service And Maintenance

Air Cleaner Service

Belly Pan

Bobtach System

Changing Engine Oil

Control Lever Lock

Cooling System Service

Cylinder Head Retorquing

Enclosure Latches

Enclosure Removal And Reinstallation

Engine Hood

Engine Lubrication Service

Fan Belt Adjustment

Fuel Pickup Tube

Fuel Specifications

Fuel System Service

Fuel Tank

Two Stage Air Cleaner With Aspirator

Hoisting The M-970

Initial 25 – 50 Hour Service

Injector Service

Lift Arm Replacement

Oil Filter Replacement

Operator Enclosure Tilt Control

Preventive Maintenance Schedule

Recommended Oil Specifications

Reworking Lift Arm Assembly

Side Panel And Grill Removal

Tire Maintenance

Transporting The M-970

Venting Fuel System

Electrical Service

Alternator Checks

Battery Installation

Battery Problems

Instrument Panels

Regulator Checks

Replacing Headlamps

Wiring Harness

Hydraulic And Hydrostatic Service

Assembling Servo Pistons

Assembling The Cylinder Block

Attaching Control Link

Attaching Servo Piston Assemblies To Swash Plate

Basic Operating Principle Of Hydraulic System

Charge Pump Removal And Reinstallation

Checking Charge Pressure

Check Valve Removal And Reinstallation

Control Valve Service

Disassembly Instructions

Disassembly Procedure

Displacement Control Valve Removal And Reinstallation

Filter Service

Hydraulic Control Valve Bank

Hydraulic Cylinder Inspection And Service

Hydraulic Fluid Cooler Service

Hydraulic Leaks

Hydraulic Pump Service

Hydraulic Service

Hydraulic Test Kit

Hydrostatic Charge Pump

Hydrostatic Circuitry

Hydrostatic Motor Manifold Block Service

Hydrostatic Motor Removal And Reinstallation

Hydrostatic Operation Principle

Hydrostatic Pump And Motor Control Adjustment

Hydrostatic Pump And Motor Displacement Control Valve

Hydrostatic Pump Removal And Reinstallation

Installing Bearing Plate

Installing Control Assembly

Installing Drive Shaft

Installing End Cap And Charge Pump

Installing Front Cover And Gasket

Installing Shaft Seal

Installing Servo Sleeves

Installing Spring Guide

Installing Swash Plate

Installing Thrust Plate

Installing Trunnions

Overhaul Of Hydrostatic Pump And Motor

Placing Valve Plate On End Cap

Pressing Cone Of Rear Bearing Into Shaft

Reassembly Procedure

Removal Of Pump Or Motor From Vehicle

Removal Of Seal From Pump Or Motor

Removing Charge Pump And Check Valves

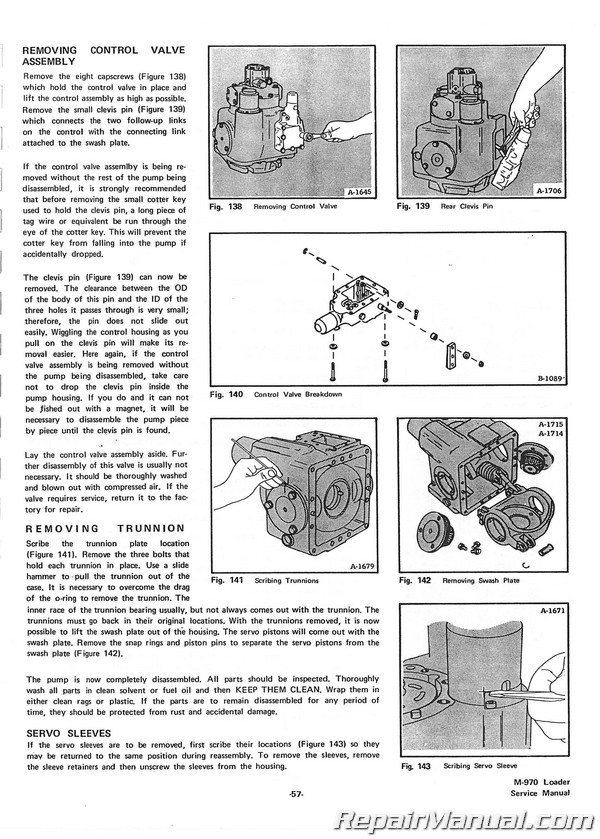

Removing Control Valve Assembly

Removing Drive Shaft

Removing End Cap

Removing Front Cover

Removing Pistons And Slipper Retainer

Removing Rear Bearing

Removing Slipper Retainer Guide

Removing Spring Guide And Cylinder Block

Removing Thrust Plate

Removing Trunnions

Removing Valve Plate And Bearing Plate

SAE Connection (37° Flare)

SAE Split Flange Connection (Bolt)

SAE Straight Thread O-ring Seal

Seal Reinstallation

Mechanical Drive

Axle Carrier Reinstallation

Axle Carrier Removal

Chaincase Service

Clark Reduction Gearcase

Clutch Service

Disassembling A Funk Gearcase

Disassembling The Axle Carrier

Final Drive Chain

Final Drive Chain Removal

Final Drive Idler Repair

Final Drive Re Installation

Gearcase Mounting

Gearcase Removal

Power Transfer Chain Adjustment

Reassembling A Clark

Reduction Gearcase

Reassembling A Funk Gearcase

Reassembling The Axle Carrier

Reduction Gearcase

Transfer Chaincase Removal

Perkins Engine Service

Assemble Pistons To Connecting Rods

Balance Unit Service

Breather Assembly

Checking The Timing Gear Backlog

Checking Valve Timing

Cooling System Service

Crankcase Ventilation

Crankshaft And Main Bearings

Crankshaft Service

Cylinder Head Gasket

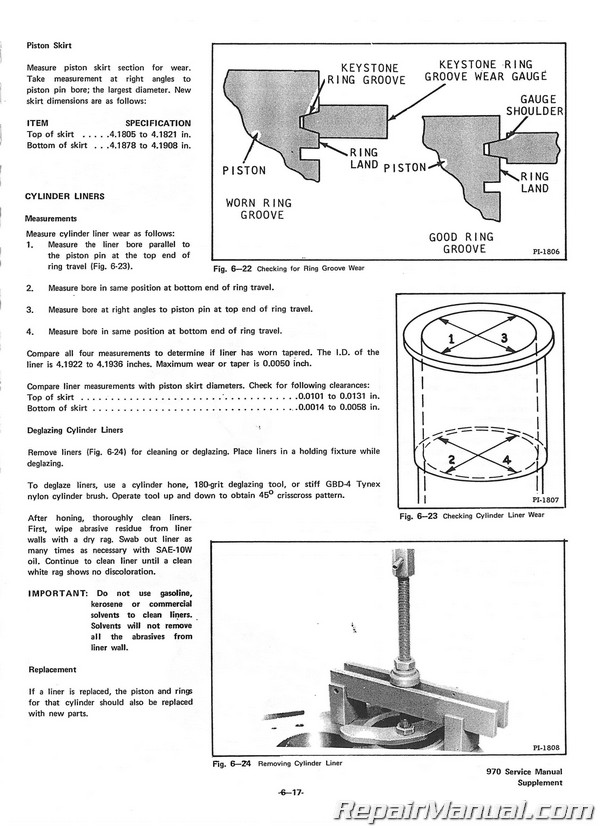

Cylinder Liners

Engine Description

Engine Number

Engine Removal (Perkins)

Flywheel Service

Fuel System Service

Injector Service

Installing Main Bearings And Thrust Washers

Installing Pistons And Connecting Rods To Cylinder Bore

Installing New Pistons

Introduction

Lubrication Oil Sump

Lubrication System

Main Bearing And Thrust Washer Removal

Milling Of Cylinder Head

Reassemble Cylinder Head

Reinstalling Cylinder Heads

Reinstalling Tappets And Camshaft

Reinstalling Timing Case Cover

Removing And Reinstalling Camshaft Gear

Removing And Reinstalling Fuel Pump Gear

Removing And Reinstalling Idler Gear And Hub

Removing Camshaft And Tapper

Removing Cylinder Head

Removing Pistons And Connecting Rods

Removing Timing Case Cover

Removing And Reinstalling Timing Case

Renewing Crankshaft Front And Seals

Renewing Cylinder Liners

Rocker Shaft Assembly

Smoke Diagnosis Chart

Valve Removal

Valve Service

Troubleshooting Perkins

Continental Engine Section

Assembling Oil Seals In Filler

Block And Oil Guard

Camshaft

Crankshaft And Main Bearings

Crankshaft End Play

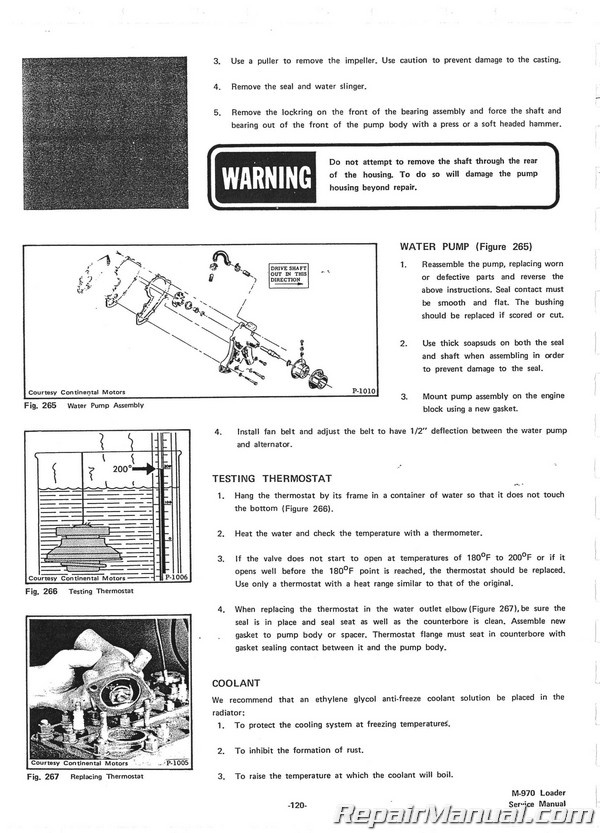

Cooling System Service

Cylinder Head

Engine Description

Engine Removal

Engine Repair And Overhaul

Fuel System

Flywheel And Flywheel Housing

Ignition System

Information For Ordering Parts

Jute Type Oil Seals

Lubrication System

Neoprene Oil Seal

Oil Pump

Pistons And Connecting Rod Service

Pistons And Piston Pins

Preparing Cylinder Walls For

Regrinding Or Reboring

Reassembling Engine

Tappets

Timing Gears

Troubleshooting Continental Engine

Valve Service

Technical Data Limits And Clearances

Forms

Specifications

Technical Data:

Continental

Perkins

Time Required For Service

Loader Torque Specifications

John Deere Engine Service

Balanced Shafts

Camshaft

Cooling System

Crankshaft, Main Bearings And Flywheel

Cylinder Block Liners Pistons And Rods

Cylinder Head And Valves

Cylinder Head Valves, Camshaft And Timing Gear Train

Cylinder Heads And Valve Train Parts

Installation

Detailed Tune-up Procedures

Engine Break-in Instructions

(After Overhaul)

Engine Tune-up

Fuel System

Lubrication System

Preliminary Engine Testing

Special Tools

Specifications

Timing Gear Train

Valve Clearance Adjustment

Valve Train