Description

This Caterpillar Grader #12F and 14E Service Manual provides detailed service information, step-by-step repair instruction and maintenance specifications for Caterpillar Grader #12F (13K1 & Up), Grader #12F (33K1 & Up), Grader #12F (89H1 & Up), Grader #14E (12K1 & Up), and Grader #14E (72G1 & Up) models. This is a reproduction of the original, out of print manual.

Caterpillar Grader #12F and 14E Service Manual Table of Contents

SYSTEMS OPERATION

Air Inlet and Exhaust System

Aftercooler

Timing Gears

Turbocharger

Valves and Valve Mechanism

Basic Block

Crankshaft

Cylinder Block and Liners

Pistons, Rings and Connecting Rods

Vibration Damper

Cooling System

Coolant for Air Compressor

Cooling System Components

980 Wheel Loader Torque Converter Cooler

Electrical System

Charging System Components

Electrical System Schematic

Other Components

Starting System Components

Fuel System (Scroll—PC)

Fuel Injection Pump

Fuel Injection Valve

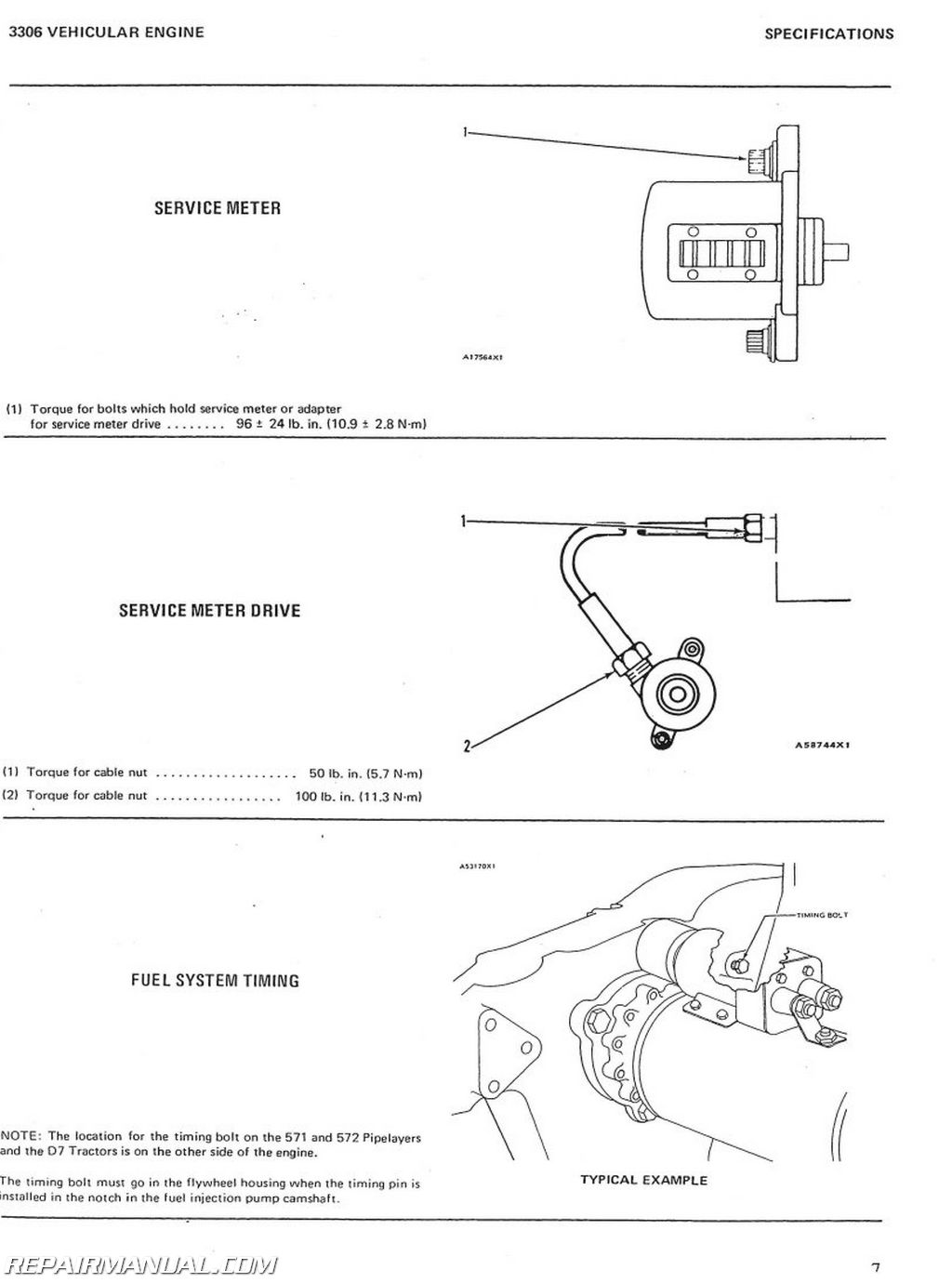

Fuel System Timing

Glow Plugs

Govenor Operation

Introduction

Fuel System (Sleeve Metering)

Adjustments to the Sleeve

Metering Fuel System

Fuel Flow after Engine Stops Running

Fuel Flow Using the Priming Pump

and Bleed Valve

Fuel Flow with Constant Bleed Valve

Fuel Flow with Siphon Break

Fuel Flow with Siphon Break and

Constant Bleed Valve

Fuel Flow without Siphon Break or

Constant Bleed Valve

Fuel Injection Pump Operation

Fuel Injection Valve (PC)

Fuel Injection Valves

Fuel Priming Pump

Fuel Ratio Control

Fuel System Operation

Fuel System Timing

Fuel System Usage Chart

Fuel Transfer Pump

Glow Plugs (PC)

Governor

Injection Nozzle (Dl)

Introduction

Siphon Break

Sleeve Position

Water Separator

General Information

Fuel System Usage Chart

Lubrication System

Lubrication System Components

Oil Flow in the Engine

Oil Flow through the Oil Filter and Oil Cooler

TESTING AND ADJUSTING

Air Inlet and Exhaust System

Checking Inlet Manifold Pressure at Torque

Converter Stall Speed

Crankcase (Crankshaft Compartment) Pressure

Compression

Cylinder Head

Glow Plug and Precombustion Chamber Removal

and Installation

Measurement of Exhaust Temperatures

Measurement of Pressure in Inlet Manifold

Procedure for Measuring Camshaft Lobes

Restriction of Air Inlet and Exhaust

Turbocharger

Valve Clearance

Basic Block

Connecting Rods and Main Bearings

Connecting Rods and Pistons

Cylinder Block

Cylinder Liner Projection

Flywheel and Flywheel Housing

Piston Ring Groove Gauge

Vibration Damper

Cooling System

Checking Fan Speed

Checking Radiator Air Flow

Filler Cap and Pressure Relief Valve

Gauge for Water Temperature

Pressure Cap

Testing the Cooling System

Testing Radiator and Cooling System for Leaks

Visual Inspection of the Cooling System

Water Temperature Regulator

Electrical System

Battery

Charging System

Shutoff Solenoid

Starting System

Fuel System

Adjustment and Cleaning 7N449 Fuel

Injection Nozzles

Checking Engine Cylinders Separately

Checking Engine Timing with 6V3100 Diesel Engine

Timing Indicator Group

Engine Speed Measurement

Finding Top Center Compression Position for

No 1 Cylinder

Flow Checking Fuel Injection Pump Timing

(PC Engines Only)

Fuel Injection Lines

Fuel System Inspection

Start-Up Procedure

Test Sequence — Precombustion Chamber (PC)

Fuel Nozzle

Testing 7N449 Fuel Injection Nozzles

Testing Capsule Type Fuel Injection Nozzles

Troubleshooting of 7N449 Fuel Injection Nozzles

Fuel System — Sleeve Metering

Fuel Injection Service

Fuel Pump Calibration

Fuel Ratio Control Setting

Fuel System Adjustments

Fuel System Setting

Governor Adjustments

Fuel System (Scroll—PC)

Checking the Fuel Injection Valves

Checking the Plunger and Lifter Washer of an

Injection Pump

Decelerator Control Adjustment

Fuel Injection Service

Fuel Rack Setting

Fuel Ratio Control Setting

Governor Adjustments

Governor Control and Decelerator Linkage

Adjustments

Governor Linkage Adjustment

Lubrication System

Oil Pressure is High

Oil Pressure is Low

Too Much Bearing Wear

Too Much Oil Consumption

Troubleshooting

Caterpillar Grader #12F and 14E Service Manual Index of Topics

Batteries

Bearings

Anti-Friction

Double Row, Tapered Roller

Heating Bearings

Installation

Preload

Sleeve Bearings

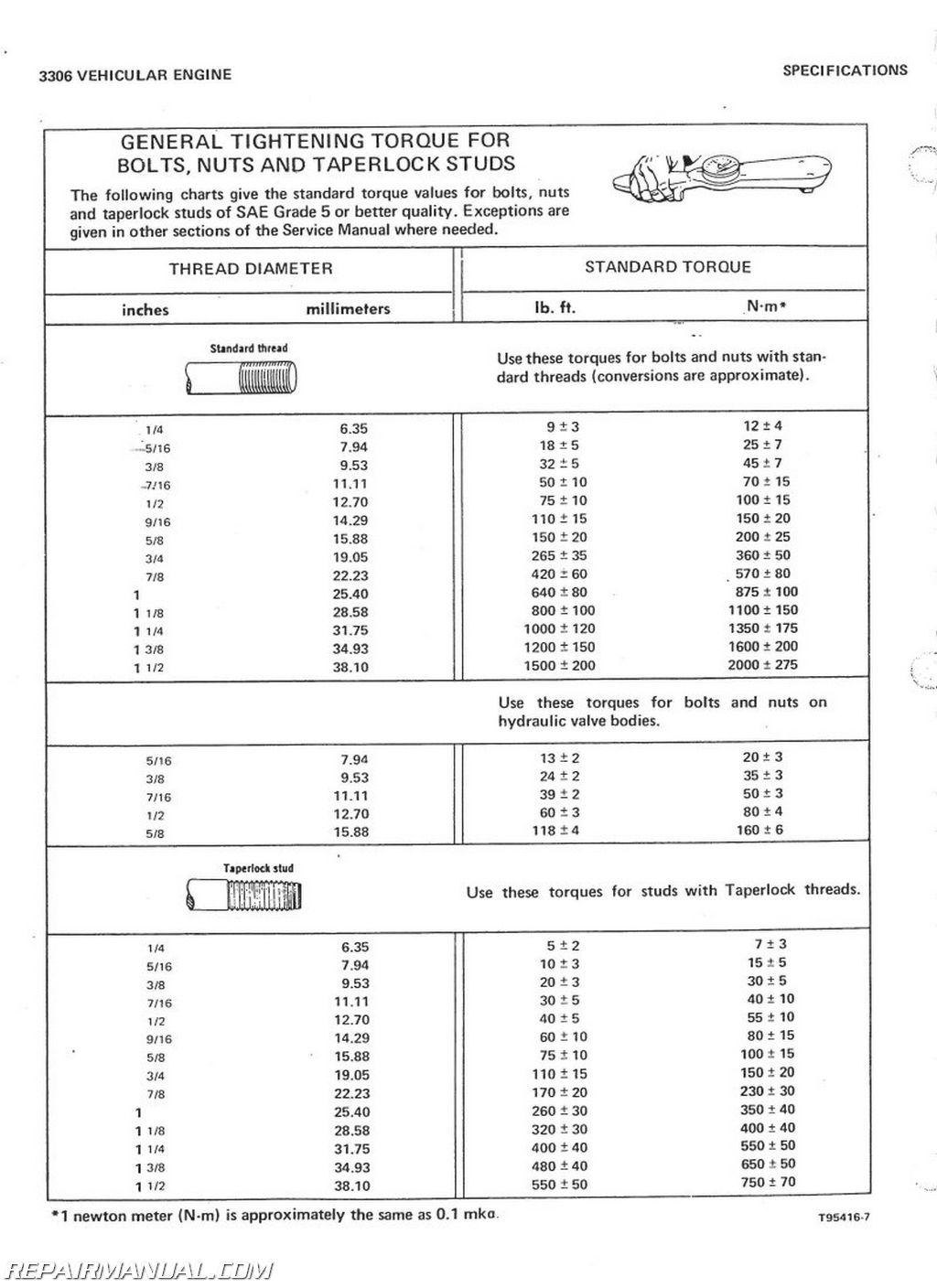

Bolts and Bolt Torque

Torque Multipliers

Torque Wrench Extension

T-T-T Procedure

Brake Linings

Cleaning and Handling of Parts

Cleanliness

Cylinders, Hydraulic

Cylinder Head Seals

Cylinder Installation

Disassembly and Assembly

Head Packing Adjustment

Removal

Seal Guide

Solid Seal Assemblies

Disassembly and Assembly

Filling and Bleeding the

Hydraulic Track Adjusters

First Operation of a Rebuilt Engine

Fractions, Decimals and Millimeters

Chart

Gaskets

Hydraulic Systems

Assembly of Fittings with Straight Threads

and O-ring Seals

Cleanliness

Cylinder Installation

Cylinders

Hydraulic Line Installation

Hydraulic Valves

Pumps

Assembly of Insert Vane Type Pumps

General

Rotation

Safety

Sealing Elements

Solid Seal Assemblies

Torques for Flared and O-ring Fittings

Torques for Other Fittings

Hydraulic Valves

Lines and Wires

Locks

Lubrication

Lubrication of Track Rollers and Idlers

Front Idlers

Track Carrier Rollers

Track Rollers

Pressing Parts

Pumps

Assembly of Insert Vane Type Pumps

General

Rotation

Relieving Track Tension

Hydraulic Adjusting Type

Screw Adjusting Type

Removal and Installation

Safety

Seals

Duo-Cone Floating

Lip-type

Service Tools

Bearing Cup Pulling Attachment Bearing Pulling Attachment

Puller Assembly (2 or 3 arm)

Push Puller

Shims

Sprocket Segment Removal and Installation

Tool Safety

Torque Multipliers

Torque Wrench Extension

SKU: JS-CT-O-225BEX2ZD

SKU: JS-CT-O-225BEX2ZD SKU: JS-CT-P-215EX14Z

SKU: JS-CT-P-215EX14Z SKU: JS-CT-P-225EX201

SKU: JS-CT-P-225EX201