Description

This 330 page, Deutz-Allis 5215 Diesel Compact 3 Cylinder 4WD Service Manual is a reproduction of the original out of print manual. This printed manual provides repair information for Deutz-Allis 5215 Diesel Compact 4WD tractors.

The engine used in the Deutz-Allis 5215 4WD Diesel Compact Tractor was developed exclusively for agricultural use and to withstand overloads and severest condition of use. It consistently provides top performance as long as it is kept properly maintained per the procedures described in this service manual. This 3-cylinder, 4-cycle, swirl chamber engine uses an indirect injection system. Forced lubrication with a trochoid pump and water cooling insure greater reliability. Cylinders are sleeveless. Four precision crankshaft bearings inserts and two selective connecting rod bearings are used. The cylinder head is shaped to provide swirl chambers, which are of the dry type. Grow plugs are installed in the swirl chambers. The crankshaft has a timing gear and a pulley at front. The main bearings use steel-backed Kelmet linings with lead-plated bearing surfaces for smoothness and durability. Crankshaft thrust is maintained by the center main journal with thrust washers which are separate from the crankshaft bearings. The thrust bearings are a Babbit alloy. The pistons are the taper and oval skirt type and are made of an aluminum alloy. Three rings are installed on the piston. Connecting rods are forged. A replaceable precision bearing insert is at the large end. The connecting rod bearing inserts use steel backed Kelmet linings and lead-plated bearing surfaces for smoothness and durability. The flywheel and the crankshaft are precisely balance to prevent engine vibration. Purchase this Deutz-Allis 5215 4WD Diesel Compact Tractor Service Manual to keep your compact tractor running in tip top shape!

Table of Contents

Engine

DESCRIPTION

SPECIFICATIONS

FITS AND TOLERANCE OF ENGINE PARTS

Cylinder and Piston

Piston Ring

Crankshaft and Main Bearings

Connecting Rods and Piston Pin (press fit type)

Connecting Rod Bearings

Exhaust Valve

Intake Valve

Exhaust Valve Seat Ring (cylinder head)

Intake Valve Seat Ring (cylinder ring)

Valve Guide (cylinder head)

Rock Arms

Valve Lifter

ENGINE TORQUE SPECIFICATIONS

BOLT TORQUE SPECIFICATIONS

DISASSEMBLY AND ASSEMBLY

Intake and Exhaust Manifolds

Disassembly and Assembly

Rocker Cover

Disassembly and Assembly

Valve Lash Adjustment

Valve Timing

Rocker Arm Assembly

Disassembly and Assembly

Rocker Assembly

Disassembly and Assembly

Cylinder Head

Disassembly

Assembly

Servicing the Cylinder Head

Inspection

Swirl Chamber Insert

Disassembly and Assembly

Valve Springs

Disassembly

Inspection

Assembly

Valve Seat Grinding

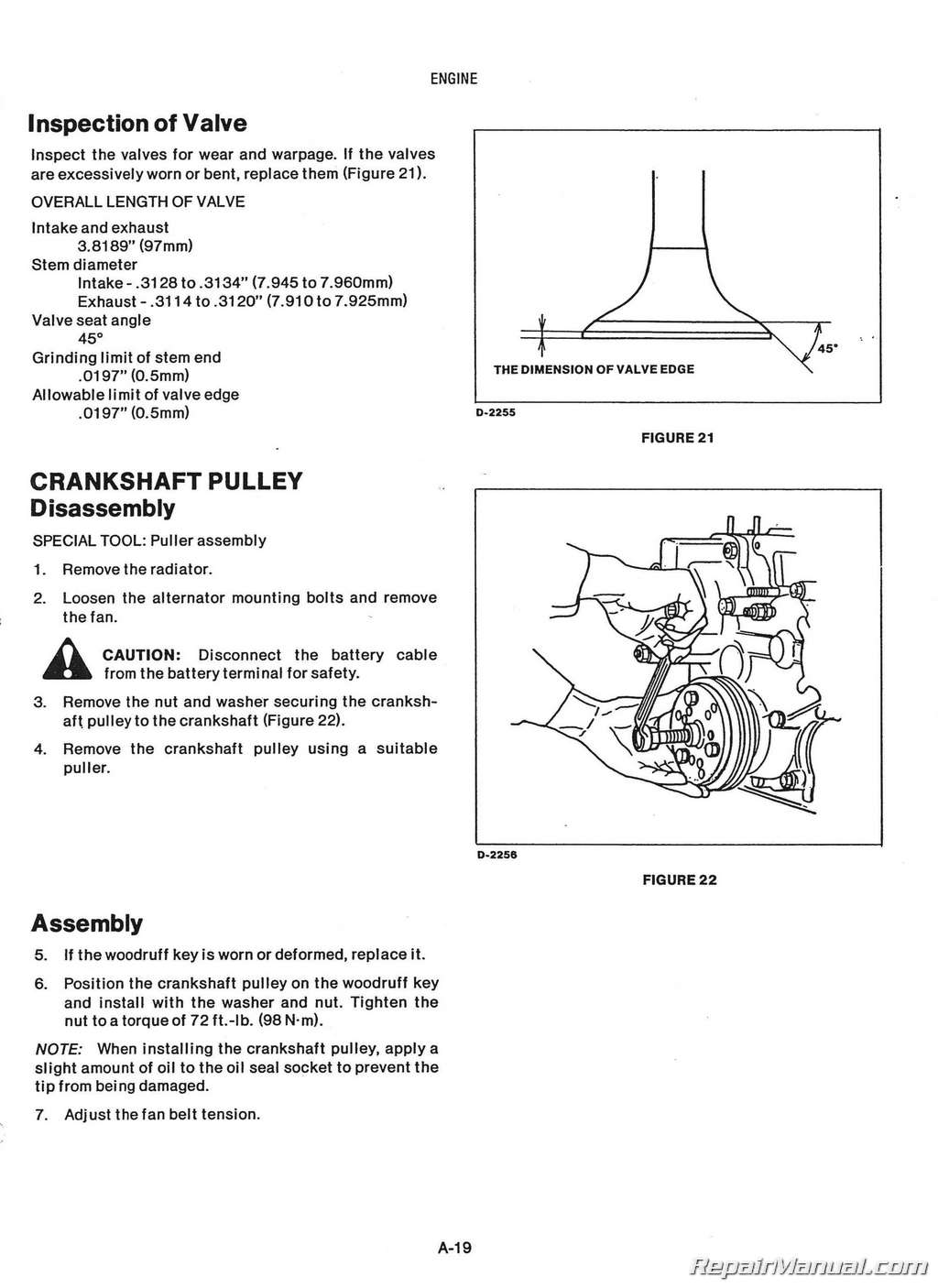

Inspection of Valve

Crankshaft Pulley

Disassembly and Assembly

Timing Gear Case

Disassembly

Assembly

Servicing

Idler Gear

Disassembly and Assembly

Camshaft Drive Gear

Disassembly and Assembly

Idler Pump Gear

Disassembly

Assembly

Hydraulic Pump Drive Gear

Disassembly

Assembly

Adjustment of End Play

Front Plate

Disassembly and Assembly

Flywheel

Disassembly

Inspection

Assembly

Rear Plate

Disassembly

Inspection

Crankshaft Rear Oil Seal

Disassembly and Assembly

Engine Sump (Oil Pan)

Disassembly and Assembly

Oil Screen

Disassembly and Assembly

Oil Pump

Disassembly and Assembly

Servicing the Oil Pump

Diassembly

Servicing the Oil Pump Cover (Relief Valve)

Disassembly and Assembly

To Check Oil Pressure

Injection Camshaft

Diassembly and Assembly

Camshaft

Disassembly

Inspection

Valve Lifters (Tappets)

Disassembly

Inspection

Assembly

Connecting Rods (Big End Bearings)

Disassembly

Inspection

Assembly

Piston and Connecting Rods

Disassembly and Assembly

Fuel Injection System

GENERAL

BLEEDING THE FUEL SYSTEM

FUEL FILTER

Disassembly and Assembly

Servicing the Fuel Filter

INJECTION PUMP

Construction

Operation

Plunger Operation

NOZZLE AND HOLDER

Construction

Opeation

INJECTION PUMP AND GOVERNOR

Construction

PUMPMODES

Stop

Start

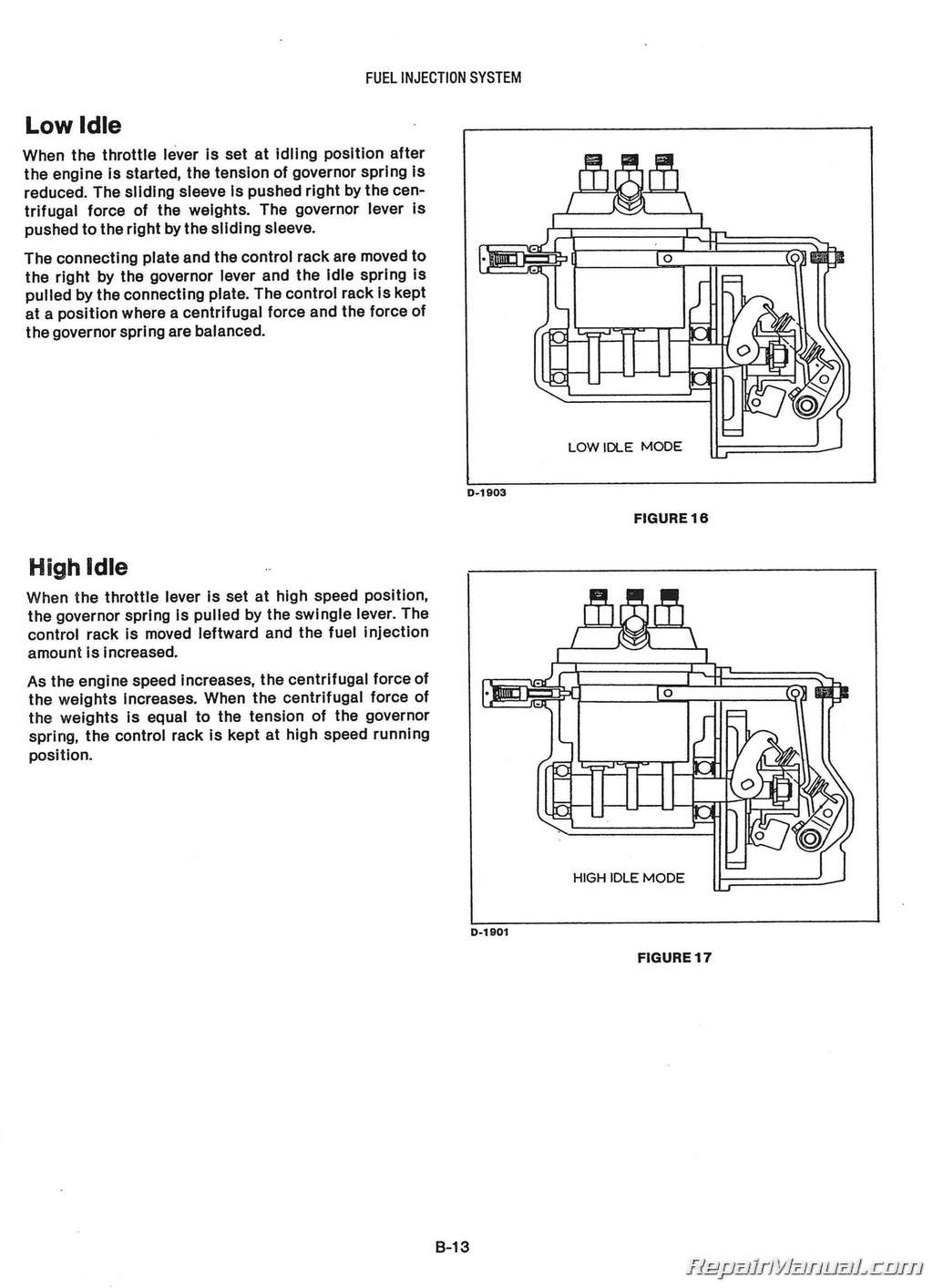

Low Idle

High Idle

Maximum Load

HANDLING FUEL

Damage Caused by Bad Fuel

Care of the Fuel System

FUEL INJECTION PUMP

Removal

Installation

Disassembly

Outline for Disassembly

Inspection

Assembly

Installation

ADJUSTMENTS

Injection Timing

Stopper Bolt

Idle Set Screw

Speed Set Screw

Ungleich Unit

Damper Bolt

UNGLEICH UNIT

Adjustment

Procedure

FUEL INJECTORS

Disassembly and Assembly

HANDLING OF NOZZLE AND NOZZLE HOLDER

Disassembly

Inspection

Repair

Assembly

Adjustment

TROUBLE SHOOTING

Engine Does Not Start

Rotation Speed of Engine is Erratic

Engine Cannot Attain Maximum Rotation Speed

Top Rotational Speed Too High

Output of Engine is Insufficient

Hydraulic System

GENERAL

POSITION CONTROL

3 POINT HITCH HYDRAULIC SYSTEM

CONTROL FUNCTIONS

Position

Floating

During Implement Lift

During Implement Lowering

HYDRAULIC CYLINDER

Removal and Installation

Disassembly

Reassembly

HYDRAULIC CYLINDER ADJUSTMENTS

Lift Arm Range

Lever Operation Force

Control Valve and Link

Floating Range

CONTROL VALVE ASSEMBLY

Disassembly

Check

Assembly

COVER ASSEMBLY

Disassembly and Assembly

Check

Adjustment of Relief Valve Pressure

RATE OF LOWER CONTROL

Faster Rate

Slower Rate

Lowering Lock

GEAR PUMP

Removal

Disassembly

Assembly

Inspection

TROUBLESHOOTING

REMOTE VALVE OIL CIRCUIT

VALVE PACKAGE INSTALLATION

VALVE HANDLE EXTENSION KIT FOR HYDROSTATIC

1 Spool

Installation

Plumbing of Tractor Auxiliary Valve

Parts List

2 Spool

Installation

PI umbi ng of Tractor Auxl 11 ary Valve

Parts List

VALVE HANDLE EXTENSION KIT FOR SYNCHRO SHIFT

1 Spool

Installation

PI umbi ng of T ractor Auxi I iary Valve

Parts List

2 Spool

Installation

PI umbi ng of T ractor Auxi I i ary Valve

Parts List

Power Train

Hydrostatic Transmission

SPECIFICATIONS

SPLITTING THE TRACTOR BETWEEN FRONT AXLE AND ENGINE

Splitting Procedure

SPLITTING THE TRACTOR BETWEEN ENGINE AND CLUTCH HOUSING

Splitting Procedure

SPLITTING THE TRACTOR BETWEEN CLUTCH HOUSING AND HST HOUSING

Splitting Procedure

SINGLE CLUTCH

CLUTCH ASSEMBLY

Disassembly, Assembly and Inspection

CLUTCH CONTROL

Disassembly, Assembly and Inspectlon

CLUTCH PEDAL

Neutral Operation

HST UNIT DESCRIPTION

CHECKING PRESSURE

Charge Pressure

High Relief Pressure

Drain Relief Pressure

CONTROL LINKAGE

Tightening Torques and Grease Points

CONTROL LEVER

Adjustment and Greasing Point

HST UNIT

Removal and Disassembly

Description and Specifications

HST UNIT DISASSEMBLY

Port Block

Motor Section

Pump Section

Charge Pump

PumpSlash Plate

Reference Values andAllowable Limits

HST UNIT ASSEMBLY

Pump Swash Plate

Pump Shaft and Charge Pump

Pump Cylinder Block Section

Motor Section

Port Block

Port Block and Case

Troubleshooting

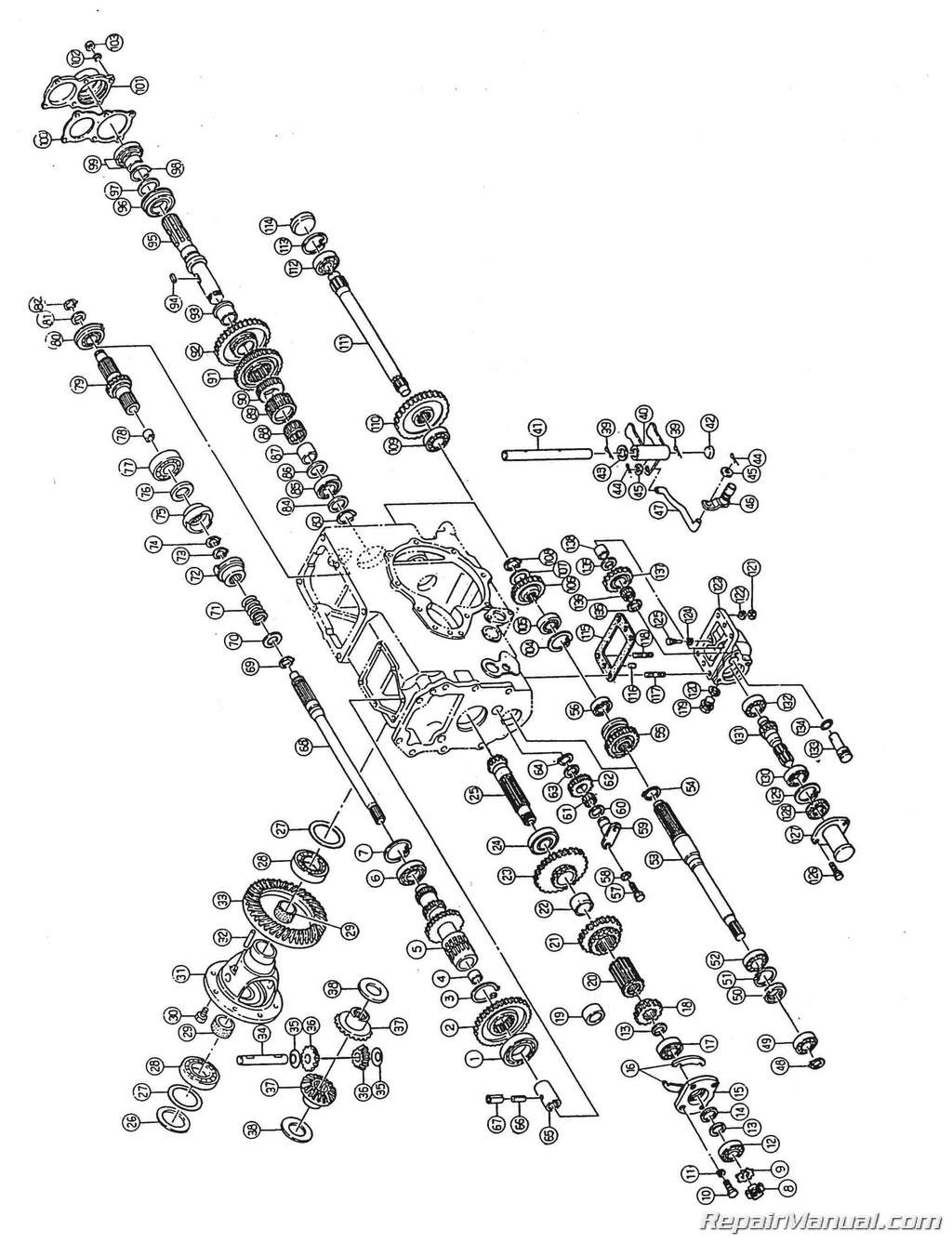

Range Transmission and Rear Main Housing Parts List

DISASSEMBLY AND ASSEMBLY

Spacer Housing and Spacer Housing Assembly

Transmission

Countershaft

Shift Control

Drive Pinion and Differential

Differential Assembly

ADJUSTMENT

Differential Assembly

Preload and Pinion Height

Ring Gear Backlash and Differential Bearing

Check of Tooth Contact

4 WD TRACTOR DISASSEMBLY AND ASSEMBLY

Front Drive Idler Shaft

Front Drive Shaft and Front Drive Shift Control

Rear Axle and Brake Parts List

BRAKE ASSEMBLY

Disassembly and Assembly

BRAKE SHOES AND DRUM

Inspection and Adjustment

Troubleshooting

REAR AXLE UNIT

Removal

Assembly and Disassembly

Adjustment of End Play

DIFFERENTIAL LOCK LINKAGE

Disassembly and Assembly

MID PTO CASE ASSEMBLY

Removal and Replacement

Disassembly and Assembly

PTO SHAFT

Disassembly

Assembly

PTO DRIVE SHAFT

Disassembly and Assembly

PTO SHIFT CONTROL

Disassembly and Assembly

PTO EXTENSION SHAFT

Disassembly and Assembly

MID PTO SHAFT

Disassembly and Assembly

Synchro Shift Transmission

SPECIFICATIONS

GENERAL

TRACTOR SEPARATION

CLUTCH ASSEMBLY

Removal

Check

Assembly

CLUTCH CONTROL

Disassembly

Check and Assembly

SLEEVE ASSEMBLY

Removal

Disassembly and Assembly

Installation

AXLE

Axial Clearance Adjustment

DIFFERENTIAL LOCK LINKAGE

Disassembly

Assembly

FRONT DRIVE SHAFT

Disassembly

Assembly

PTO SHAFT

Disassembly and Assembly

Separate Rear Housing from Transmission U nit

DIFFERENTIAL ASSEMBLY

Disassembly and Assembly

Check

RING GEAR BACKLASH

Adjustment

TOOTH CONTACT CHECK

TRANSMISSION

SHIFT COVER

Assembly

MAIN SHAFT

Disassembly and Assembly

COUNTER SHAFT

Disassembly

C heck

Axial Clearance Adjusment

COUNTERSHAFT

Assembly

REVERSE IDLER GEAR

Disassembly

Axial Clearance Adjustment

RANGE SHIFT

Disassembly

Assembly

DRIVE PINION SHAFT

ADJUSTMENTS

Beari ng Case Clearance

Pinion Height

DRIVE PINION SHAFT

Axial Clearance Adjustment

Installation

PTO SHIFT

Disassembly and Assembly

PTO SAFETY SWITCH

PTO SHAFT

Adjustment

BRAKE

Disassembly and Assembly

Front Axle, 4 Wheel Drive

GENERAL

Front Axle Cross Section

4 Wheel Drive

GEAR CASE COVER ASSEMBLY

Removal

Replacement and Disassembly

Assem bI y

CASE SUPPORT AND LIFT BOLT

Disassembly and Assembly

FRONT AXLE

Disassembly

I n spect i on

As se m b I y

Reassembly

FRONT GEAR CASE

Disassembly

FRONT AXLE CASE

Disassembly

Asse m b I y

DIFFERENTIAL CARRIER AND BEVEL PINION

Disassembly

Inspection

Assembly

DIFFERENTIAL ASSEMBLY

Disassembly and Assembly

Inspection

BEVEL PINION ADJUSTMENTS

Preload (Initial Torque)

Pinion Height

Backlash

TOOTH CONTACT

Inspection

Correction

FRONT AXLE UNIT

Disassembly

Assembly

Adjustment of End Play

Electrical System

ELECTRICAL SYSTEM WIRING DIAGRAM

BATTERY

HYDROMETER TEST

Charge Method

INSTRUMENTS AND CONTROLS

TACHOMETER

Disassembly and Assembly

LIGHT SWITCH

General

Disassembly and Assembly ,

KEY SWITCH

General

Disassembly and Assembly

LEGEND PANEL

Alternator Warning Light

Low Fuel Level Light

Engine Oil Pressure

Glow Lamp

Legend Panel Disassembly and Assembly

Bulb Replacement

FUEL LEVEL SENDING UNIT

Disassembly and Assembly

OIL PRESSURE SWITCH

Disassembly and Assembly

GLOW PLUGS

Disassembly and Assembly

TEMPERATURE WARNING LIGHT

Disassembly and Assembly

COOLANT TEMPERATURE SWITCH

Disassembly and Assembly

FLASHER UNIT

Disassembly

FUSE BLOCK

Disassembly and Installation

STARTER SAFETY SWITCHES

General

Disassembly

Testing

Installation

Bulbs

VOLTAGE REGULATOR

Testing

ALTERNATOR

Alternator Components

Disassembly and Assembly

Testing

TROUBLESHOOTING

STARTER

SPECIFICATIONS

MAGNETIC SWITCH

Disassembly

REAR COVER AND BRUSH HOLDER

Disassembly

YOKE AND ARMATURE

Disassembly

PINION GEAR

Disassembly

STARTER TESTING

Yoke (Field Coil) Check

Insulation Check

Armature Check

Armature Insulation Check

ARMATURE ASSEMBLY

Commutator Check

Insulator Check

Armature Shaft Check ,

BRUSH HOLDER CHECK

Brush Movement and Inspection

Holder Insulation Check

Brush Spring Tension

MAGNETIC SWITCH

Shunt Coil Check

Serial Coil Check

Pinion Check

TROUBLESHOOTING

Chassis

HOOD ASSEMBLY

Removal and Adjustment

HOOD RELEASE

Disassembly and Assembly

INSTRUMENT PANEL

Disassembly and Assembly

CENTER CONSOLE AND FENDERS

Disassembly and Assembly

FOOT RESTS

Disassembly and Assembly

FUELTANK

Disassembly and Assembly

HAND THROTTLE LINKAGE

Disassembly and Assembly

Adjustment

MANUAL STEERING

General

Di sassembly

Reassembly

FRONT AXLE, TWO WHEEL DRIVE

TOE IN

Adjustment

FRONTHUB

Inspection and Reassembly

SPINDLE SHAFT

Disassembly and Assembly

FRONT AXLE CENTER BEAM

Inspection

Assembly

CENTER SECTION

Disassembly and Assembly

SPINDLE HOUSING BUSHINGS

Disassembly and Assembly

SKU: JS-WI-S-VH4

SKU: JS-WI-S-VH4 SKU: JS-KOM-S-D20AP-PLUS

SKU: JS-KOM-S-D20AP-PLUS SKU: JS-DE-S-ENG912-PLUS

SKU: JS-DE-S-ENG912-PLUS