Description

This 104 page, Ford TW10 TW20 Tractor Operators Manual is a reproduction of the original, out of print, manual. This manual has been developed to assist you in understanding how to operate and maintain Ford TW10 and TW20 1978-1980 Tractors. Before operating the tractor, become familiar with the controls and instruments discussed in this manual. After familiarizing yourself with the controls and instruments, follow the subsequent instructions in the Operation Section to obtain optimum and safe performance from the tractor.

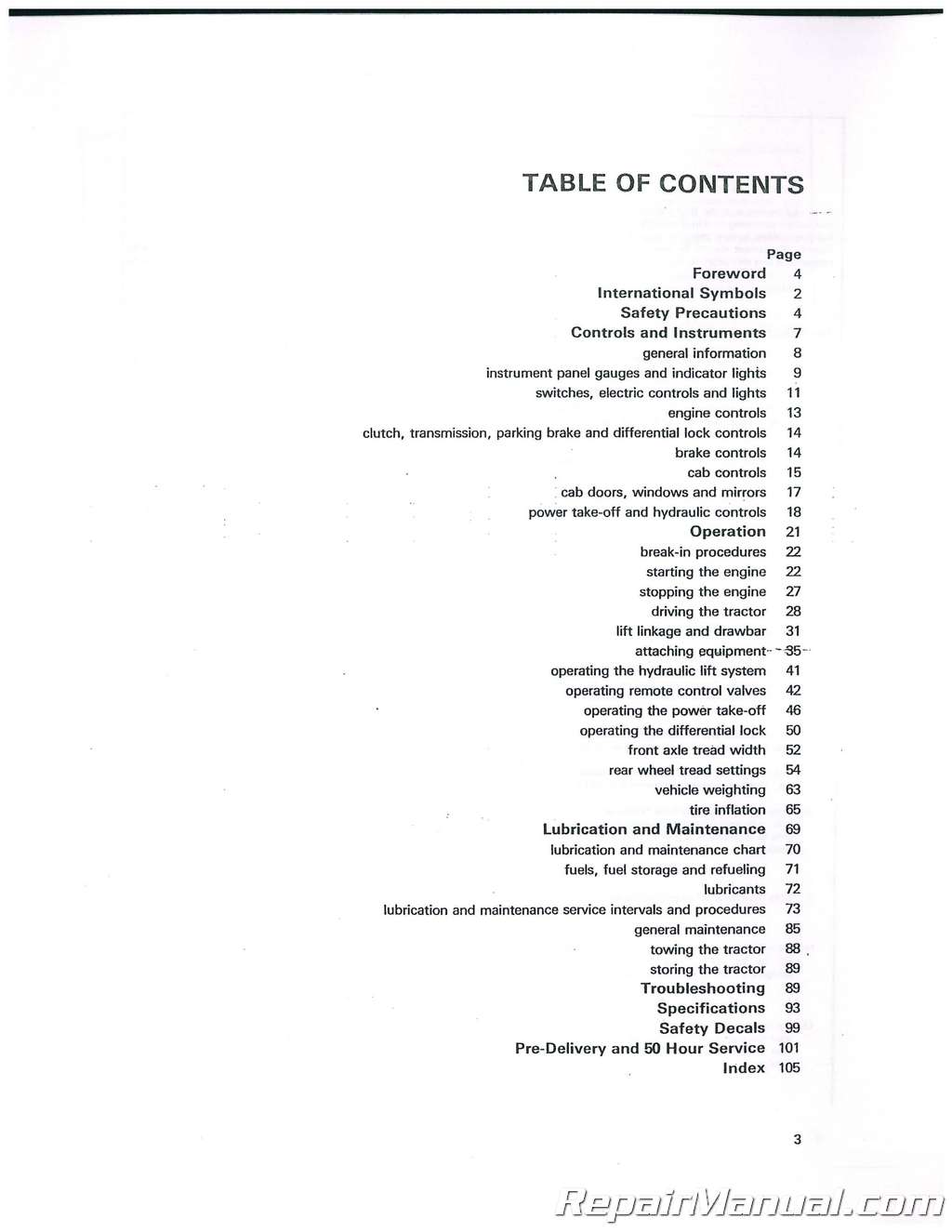

This manual contains a list of safety precautions, a discussion of the controls and instruments, procedures for operating the tractor, a maintenance schedule, a brief troubleshooting section, and a specification section. The manual also contains a list of pre-delivery and 50 hour checks which should have been performed by your Ford Tractor-Equipment Dealer. Follow the break-in, operation, and maintenance instructions to keep it in this “ready to go” condition. A vehicle identification plate is located above the right front corner of the radiator and is accessible by removing tho right front grille panel. The numbers on the identification plate are important if your tractor requires service in the future.

Table of Contents

Foreword

International Symbols

Safety Precautions

Controls and Instruments

General Information

Instrument Panel Gauges and Indicator Lights

Switches, Electric Controls and Lights

Engine Controls

Clutch, Transmission, Parking Brako and Differential Lock Controls

Brake Controls

Cab Controls

Cab Doors, Windows and Mirrors

Power Take-Off and Hydraulic Controls

Operation

Break-In Procedures

Starting the Engine

Stopping the Engine

Driving the Tractor

Lift Linkage and Drawbar

Attaching Equipment-

Operating the Hydraulic Lift System

Operating Remote Control Valves

Operating the Power Take-Off

Operating the Differential Lock

Front Axle Tread Width

Rear Wheel Tread Settings

Vehicle Weighting

Tire Inflation

Lubrication and Maintenance

Lubrication and Maintenance Chart

Fuels, Fuel Storage and Refueling

Lubricants

Lubrication and Maintenance Service Intervals and Procedures

General Maintenance

Towing the Tractor

Storing the Tractor

Troubleshooting

Specifications

Safety Decals

Pre-Delivery and 50 Hour Service

Index of Topics

Air Cleaner Servicing

Air Conditioning

Air Conditioning Compressor Belt

Air Conditioning Condenser – Cleaning

Air Conditioning System

Alternator Belt Adjustment

Attaching Equipment

Battery

Brakes – Oil Level

Brake Pedals

Brake Pedal Connecting Lock

Cab Air Filters

Cab Controls

Clutch Pedal

Dutch Pedal Adjustment

Cold Weather Starting

Differential Lock Operation

Differential Lock Pedal

Drawbar Adjustments

Driving the Tractor

Dual Power Pedal

Engine Air Inlet Hoses

Engine Controls

Engine Oil Change

Engine Oil Check

Engine Starting

Engine Stopping

Fan Belt Adjustment

Fan Switch

Front Axle

Front Axle Wheels

Fuel Injectors

Fuels

Fuel System Filter – Changing

Fuel System Filter – Draining

Fuses

Gauges

General Maintenance

Gearshift Lever

Hydraulic Cylinders – Connecting

Hydraulic Lift Controls

Hydraulic Lift Operation

Hydraulic System Filters

Indicator Lights

Instruments

International Symbols

Jumper Cables

Lift Linkage

Lift Linkage Removal

Light Bulbs

Lubricants

Lubricating

Clutch Pedal Linkage

Front Axle Spindles

Front Axle Supports

Front Wheel Bearings

Mirrors

Oil Cooler Cleaning

Parking Brake

Power Steering Oil Level

PTO Controls

PTO Equipment – Attaching

PTO Operation

PTO Shafts

Quick Hitch Installation

Radiator Cleaning

Radiator Coolant

Radios

Rear Axle/Transmission/

Hydraulic Oil Change

Rear Axle/Transmission/

Hydraulic Oil Level

Rear Wheels

Rear Wheels – Duals

Rear Wheels – Manual Adjust

Roar Wheels – Power Adjust

Remote Control Valves

Remote Cylinder and Equipment

Operation

Roll-Over Protective Structures

Safety Decals

Safety Precautions

Seat Belts

Seats

Specifications

Storing the Tractor

Switches

Tire Inflation

Tire Pressure – Checking

Towing tho Tractor

Transmission Controls

Troubleshooting

Weighting

Windows

Windshield Washer

Windshield Wipers

Sample Content

The fuel injectors should be removed and taken to your Ford Tractor-Equipment Dealer every 600 hours to have them checked for proper adjustment and per- formance. Improperly adjusted or faulty injectors reduce engine horsepower output and increase fuel consumption. Use the following procedures for removal, installation and bleeding of the fuel injectors. Figure 125 Removing and Installing the Fuel Injectors 1. Leak-Off Line Nut 3. Injector Bolts 2. Injector 4. Fuel Line Nut To remove the fuel injectors: 1. Disconnect the leak-off lines. Figure 125, by removing the leak-off line attaching bolts (1) on each injector. Disconnect the injector fuel lines (4) on each injector. 2. Loosen all the fuel injector bolts (3) a couple of turns. 3. Pull out the engine stop control and crank the engine to unseat the injectors. If the injectors do not unseat, carefully pry them loose. Remove the bolts. Remove the injectors.

SKU: FO-S-CL35-CL45

SKU: FO-S-CL35-CL45 SKU: JS-FO-S-455-TLB

SKU: JS-FO-S-455-TLB SKU: JS-FO-O-9N

SKU: JS-FO-O-9N