Description

This International Harvester 340, 460 and 560 Tractor Service Manual is a thick two volume set provides detailed service information, step-by-step repair instruction and maintenance specifications for International Harvester 340, 460 and 560 gas, LP and Diesel tractors. Includes 461 pages.

This is a high quality reproduction of the original, out of print, book.

Covers the chassis of Farmall and International tractors: 340, 460, and 560 with engines: C-221, C-263, C-291, C-301, D-236, D-282.

The general construction of these tractors is similar to the previous, displaced models in that the rear frame, clutch housing and engine is bolted together into a rigid unit. Farmall models, with the exception of the F-340 and the International models with the excep tion of the 1-340 and 1-460 use side channels bolted to the clutch housing, engine and upper bolster. The complete new styling of the Farmall 340, 460 and 560 and the International 340, 460, and 560 tractors provides a modern up-to-date appearance of rugged power. All are available as gasoline powered models and the 460 and 560 series also includes diesel models.

Table of Contents

General Information

Specifications

Engine

Lubrication system (Engine)

Fuel system, gasoline

Fuel system, diesel

Cooling system

Engine clutch

Transmission

Power take-off

Brakes

Differential and final drive

Chassis

Hydraulic equipment

Electrical equipment

Torque specifications

Gas Engines Section

Specifications

Special Service Tools Required

Service Procedure

Engine Removal

Crankshaft Pulley Removal

Valve Guides

Valve Seats and Valve Seat Inserts

Roto-Caps and Roto-Coils

Cylinder Head Installation

Valve Timing

Valve Lash Adjusting Procedure

Heat Control Valve

Camshaft

Checking Camshaft Lobe Lift (Camshaft in Engine)

Checking Camshaft Lobe Wear (Camshaft Removed from Engine)

Engine Governor

Crankshaft Bearing Caps

C-221 and C-263 Sleeve Fit

Description and General Information

Inspection and Repair

Installation

C-291 Sleeve Fit

General Information

Installation

Ram Pressures

Piston Fit in Sleeve or Bore

Piston Ring Installation (C-221 and C-263 Engines)

Water Pump

Oil Pump

Oil Filter Assemblies

Cast Iron Oil Filter Base

Service (Cast Iron Oil Filter Base)

Die Cast Oil Filter Base

Service (Die Cast Oil Filter Base)

Break-In Procedure of Rebuilt Gasoline and LPG Engines

“Run-In” When Dynamometer is Not Available

“Run-In” When Dynamometer is Available

Gasoline Fuel System

Specifications

General Description

Carburetors

Operation

Fuel Supply System

Idling System

Load System

Starting System

Liquid Level Check

Removal and Installation

Inspection and Repair

Throttle Body and Fuel Bowl

Throttle Plate

Float Assembly

Fuel Needle Valve and Seat

Adjusting Screws and Seats

Venturi and Jets

Assembly and Adjustment

LPG Fuel Systems

Specifications

Safety Precautions

General Description

Operation

Fuel Tank and Fittings

Fuel Filter Assembly

Carburetor and Regulator Vaporizer

Engine Stopped – Fuel On

Starting

Idling

Part Throttle

Full Throttle

Trouble Shooting

Regulator—Vaporizer Service

Removal and Installation

Inspection and Repair

Assembly and Adjustment

Regulator “Testing

Carburetor Service

Removal and Installation

Inspection and Repair

Fuel Adjustments

Fuel System Diesel Engine Models D-236, D-282, and D-301 Service Manual

Specifications

General Description and Operation

Filter System

Factors Affecting Pump and Nozzle Life

The Injection Pump

Load Advance

Automatic Speed Advance (Later Model)

njection Nozzles and Precombustion Chambers

Trouble Shooting

Checks and Adjustments

Fuel Shut-Off Adjustment

Governor Linkage Hook Adjustment

High and Low Idle Speed Adjustment

Governor Control Adjustment

Transfer Pump Adjustments

Air Leaks in Suction Side of Fuel System

Inefficient Transfer Pump or Malfunctioning Pressure Regulating Valve

Transfer Pump Pressure

Fuel Return Line Plugged or Restricted

Delivery Valve and Rotor Check

Broken Delivery Valve Spring

Pump Timing and Rotor Rotations

Load Advance Adjustment

Speed Advance Adjustment

Glow Plugs

Compression Pressure

Torque Screw Adjustment

Leaf-Spring Adjustment

Injection Pump Service

Pump Removal

Drive Shaft Removal

Pump Disassembly

End Plate Assemblies

Inspection and Repair

Reassembly

Pump Drive Shaft and Injection Pump Installation

Injection Nozzle and Precombustion Chamber Service

Bosch-Model ADE

Removal

Testing

Preliminary Inspection

Disassembly

Inspection and Repair

Reassembly and Testing

Installation

IH Midget or Micro Nozzles

Disassembly

Inspection and Repair

Reassembly

Testi ng

Precombustion Chambers

Priming Pump

Induction System Service

Special Service Tools

Fuel System Diesel Engine Models D-236, D-282, and D-301 Service Manual

Specifications

Description and Principles of Operation

General Description

General Information

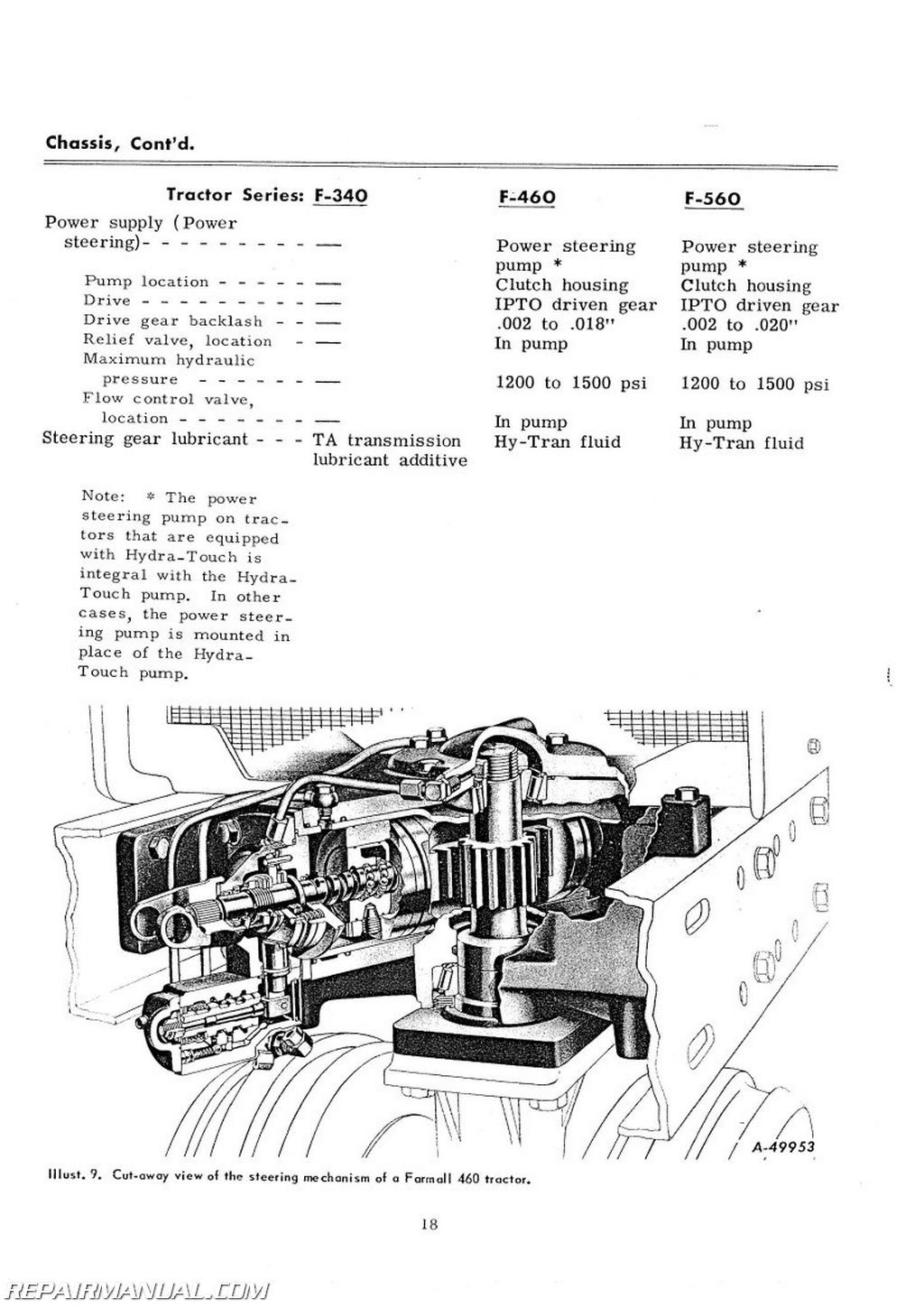

Power Steering

Manual Steering

Power Steering

Disassembly

Inspection and Repair

Assembly

Manual Steering

Disassembly and Inspection

Assembly

Power Steering Pump

Trouble Shooting Chart

Steering and Front Axle Assembly Manual

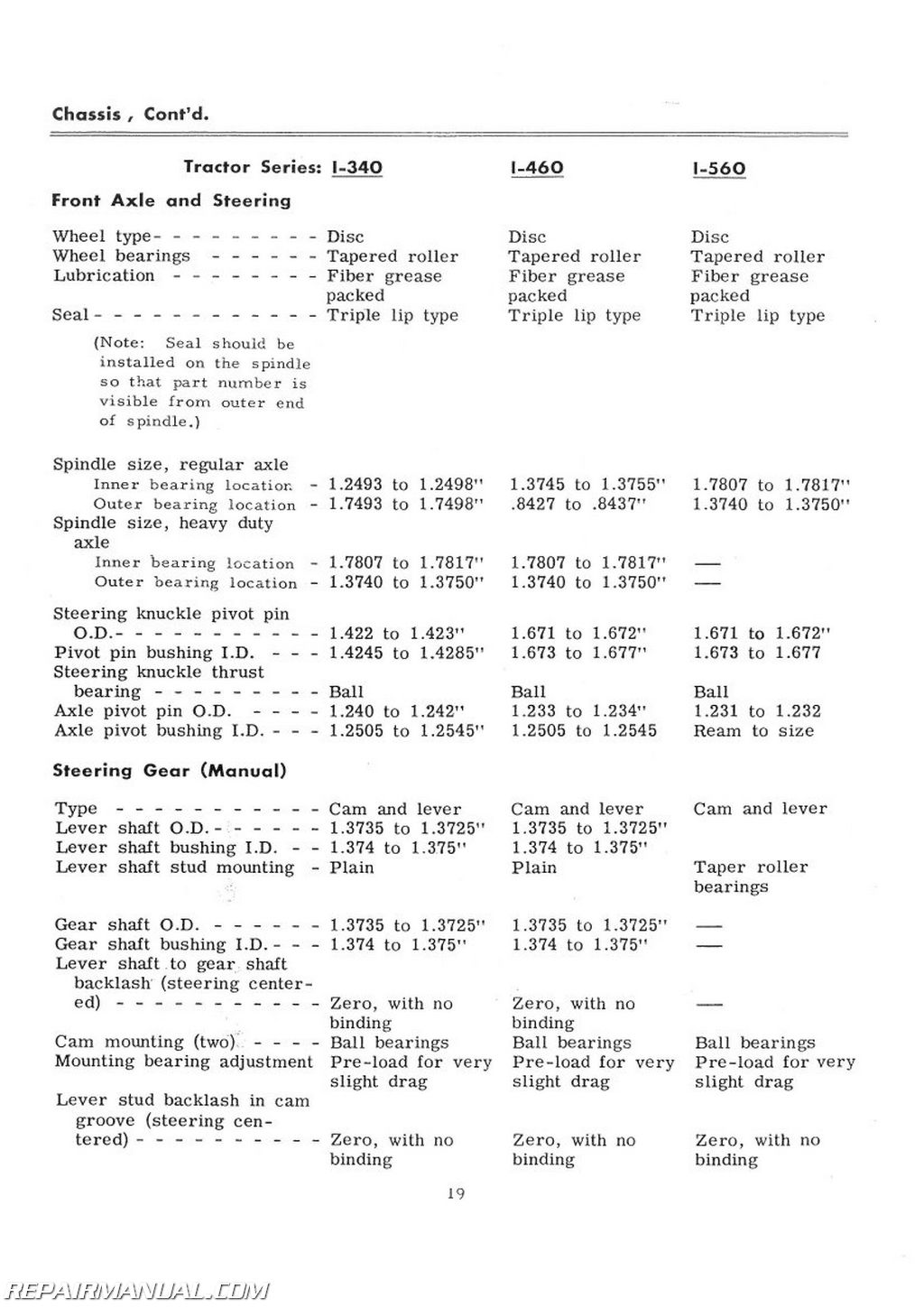

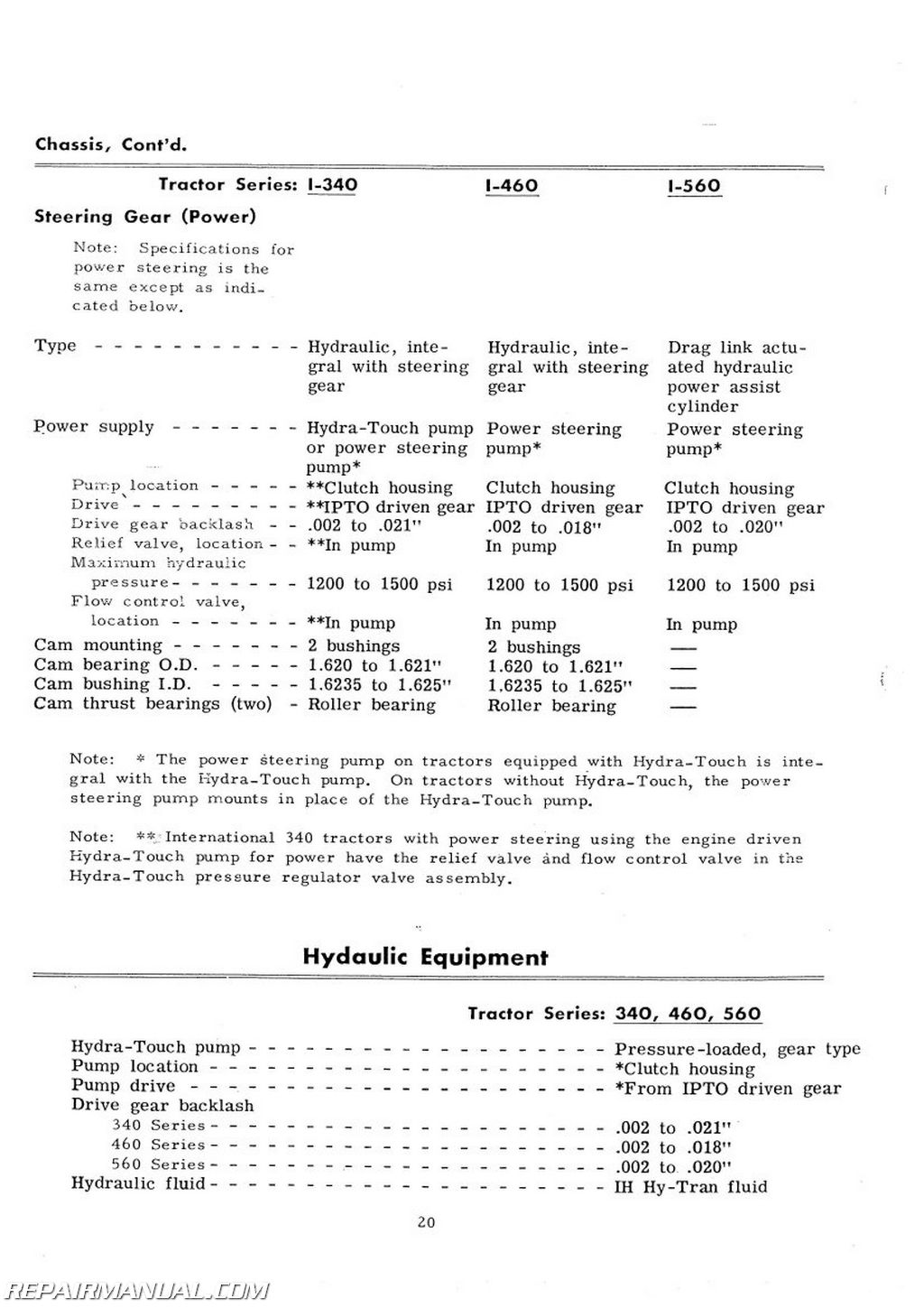

Specifications

Description and Principles of Operation

General information

Factors effecting steering Camber

Caster

Toe-in

Steering geometry

Preliminary check-up

Front Wheels and Bearings

Removal and disassembly

Inspection, repair, and servicing

Assembly on axle

Axle and Extension, Steering Knuckle and Arm Disassembly

Inspection and repair

Assembly

Steering Gear and Arms Disassembly

Inspection and repair

Assembly

Adjustments

Cam thrust

Cross-shaft gear teeth

Lever stud in cam groove

Steering gear arm position

Final Assembly and Adjustment Assembly

Straight ahead adjustment

Toe-in adjustment

Hydraulic Power Steering Gear

General description

Principles of operation

Disassembly

Inspection and repair

Assembly and adjustments

Hydraulics (Pumps)

Hydraulic Pumps

Introduction

Rotary Gear Pumps

Gears

Pump Body

Engine-Mounted Pumps

Removal

Disassembly

Inspection and Repair

Reassembly

Installation

Internal Pumps (Thompson)

Removal

Disassembly

Inspection and Repair

Reassembly

Installation

Internal Pumps (Cessna)

Removal

Disassembly

Inspection and Repair

Reassembly

Installation

Cessna Power Steering Pump

General Description and Operating Principles

Removal

Pump Service

Thompson Power Steering Pump

General Description and Operating Principles

Pump Service

Ilydreco Pump

General Description

Disassembly

Inspection and Repair

Reassembly and Adjustment

Installation

Webster Electric Pump

Disassembly

Inspection and Repair

Reassembly

Installation[

Eaton Pump

General Description and Operating Principles

Disassembly

Inspection and Repair

Reassembly

Hydraulics (Trouble Shooting – Test Procedures – Specifications)

Introduction

Trouble Shooting Chart

Test Procedure

Specifications

Trouble Shooting

Flushing and Cleaning the Hydraulic System

Hydraulic System Test Procedure Using the IH Flo Rater

About the Instrument

Construction of the Flo Rater

Section 1

Preparation for Testing

Section 2

Connecting the Flo Rater

Section 3

Test Temperature of Fluid

Section 4

Testing Free Flow Rate

Section 5

Testing Main Relief Valve and/or Flow Divider Valve Action

Section 6

Testing for Pump Pressure Leaks At Spool Lands and for Internal Cylinder Leaks

Section 7

Testing Unlatching Valve Action

Section 8

Testing Pressure Regulator By-pass Pressure

Section 9

Testing Flow Rate at Rated Speeds and Test Pressure

Section 10

Testing Power Steering Circuits or Systems

Test Specifications

Hydraulic Valve Specifications

Hydraulic Pump Allowable Wear Specifications

Hydraulic Pump Manufacturing Specifications (New Part Dimensions)

Hydraulic Pump Allowable Wear Specifications

Hydraulic Pump Manufacturing Specifications (New Part Dimensions)

Torque Amplifier 300 Series

Specifications

General Description

Principles of Operation

Regular (Direct Drive)

Torque Amplifier Drive

Splitting the Tractor

Front Section Split

Removing Clutch Housing from Rear Frame

Removal and Assembly

Removing the IPTO Drive Shaft, Engine

Clutch Shaft and TA Clutch

Torque Amplifier Unit

Inspection

Primary Sun Gear and Shaft

Planet Carrier, Gears and Bearings

Overrunning Clutch

Secondary Sun Gear and Transmission Drive Shaft

TA Clutch and Release Assembly

Assembly and Installation

Torque Amplifier Unit

TA Clutch, Engine Clutch Shaft and IPTO Driving Shaft

Attaching Clutch Housing Assembly

to the Rear Frame

Recoupling the Tractor

Tractor Final Assembly,

Adjustment and Inspection

Brake Service

Specifications

General Description

Disassembly, Inspection and Repair

Assembly and Installation

Operational Brake Test

Transmission and Final Drive

Introduction

General Information

Specifications

Transmission

Removal and Disassembly

Inspection and Repair

Reassembly and Installation

Rear Axle and Differential

Removal and Disassembly

Inspection and Repair

Reassembly and Installation

Final Drive (Planetary 660 Series)

Removal and Disassembly

Inspection and Repair

Reassembly and Installation

Trouble Shooting

Independent Power Take-Off 400 Series

Specifications

General Description

Principles of Operation (Rear Unit)

Engaged Position

Disengaged Position

Splitting the Tractor

Front Section Split

Removing Clutch Housing from Rear Frame

Removal and Disassembly

IPTO Driving Shaft and Engine Clutch Shaft

IPTO Driven Gear and Shaft

Removing the IPTO Rear Unit

IPTO Extension Shaft

Disassembly of the IPTO Rear Unit

Inspection

Bearings

Oil Seals

IPTO Driving Shaft and Hub

IPTO Driven Gear and Shaft

Seasonal Disconnect

Extension Shaft and Coupling Shaft

Rear Unit

Reassembly and Installation

Rear Unit

IPTO Extension Shaft

IPTO Driven Gear and Shaft

IPTO Driving Gear and Shaft

Recoupling the Tractor

Attaching the Clutch Housing

Assembly to the Rear Frame

Connecting the Clutch Housing and Front Section of the Tractor

Tractor Final Assembly and Adjustment

Special Tools Needed

SKU: JS-IH-O-B

SKU: JS-IH-O-B SKU: IH-O-F20

SKU: IH-O-F20 SKU: JS-IH-O-F12

SKU: JS-IH-O-F12