Description

This 225 page, International Harvester Cub and Cub Lo-Boy Service Manual is a reproduction of the original out of print factory manual. This manual serves as a comprehensive guide to repairs and provides detailed information, instructions, and specifications for maintaining, repairing, and servicing International Harvester Cub and Cub Lo-Boy tractors.

Table of Contents

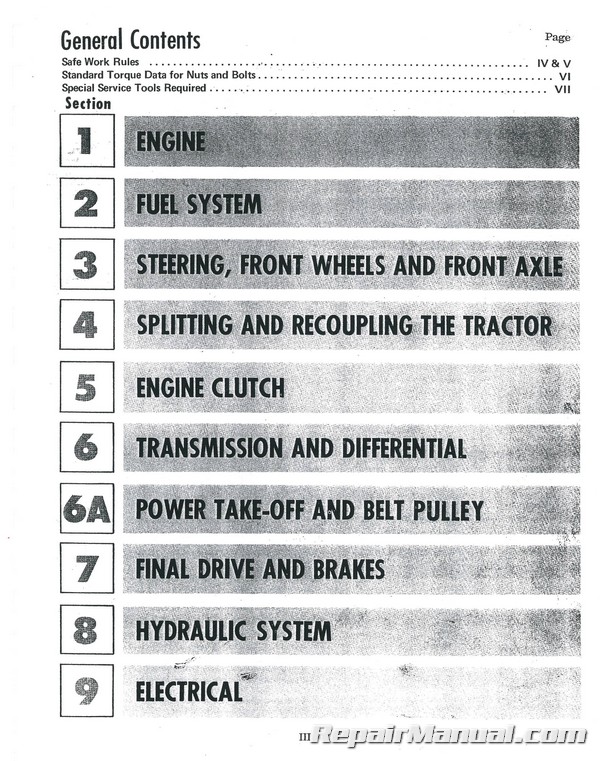

Section 1 – Engine

Engine Specifications

Engine Removal

Engine Installation

Cylinder Head

Valves

Valve Lash Adjusting Procedure

Removing Valves

Inspection

General

Valves

Valve Seat Retainer Keys

Valve Guides

Valve Seats

Rotocap

Testing Rotators

Reconditioning

Valve Guides

Valves

Valve Seats

Refacing Seats

Reassembly

Connecting Rods, Pistons and Piston Rings

General

Connecting Rods

Pistons

Piston Rings

Piston Pins

Removal

Disassembly

Inspection and Repair

Reassembly

Piston Fit in Bore

Bearing Fitting Procedure

Installation

Crankcase Cylinder Re-Boring Procedure

When to Re-Bore

Preparing the Block

Re-Boring

Honing

Cleaning

Checking Clearance

Timing Gear Train and Front Cover

General

Camshaft

General

Crankshaft and Main Bearings

General

Lubricating Oil Pump

General Description

Gil Pump

Pressure Regulator Valve

Removal and Disassembly

Inspection and Servicing

Reassembly

Cooling System

General Description and Operation

Removal of Radiator Assembly

Inspection and Repair

Installation of Radiator Assembly

Cooling Fan Service

Troubleshooting

Tune-Up

Section 2 – Fuel System

Fuel System Specifications

Carburetor

General Description

Carburetor Operation

Liquid Level Check (carburetor on Engine)

Removal and Installation of Carburetor

Inspection and Repair

Assembly and Adjustment

Diagnosing Engine Troubles

Governor

Principles of Operation

Removal, Inspection and Repair

Installation and Adjustment

Section 3 – Steering, Front Wheels and Front Axle

Specifications

Front Wheels and Bearings

Removal

Inspection and Repair

Installation

Removal and Disassembly of Front Axle Assembly

Inspection and Repair

Reassembly and Installation of Front Axle Assembly

Steering Assembly

Removal

Disassembly

Inspection and Repair

Reassembly

Installation

Adjusting the Toe-In

Section 4 – Splitting and Recoupling the Tractor

Front Section Split

Recoupling

Rear Section Split

Recoupling

Section 5 – Engine Clutch

Specifications

Removal

Disassembly

Inspection and Repair

Reassembly

Installation

Clutch Adjustment

Section 6 – Transmission and Differential

Specifications

General

Removal

Disassembly

Differential,

Transmission

Inspection and Repair

Reassembly and Installation

Section 6A – Power Take-Off and Belt Pulley

Specifications

Belt Pulley

Removal and Disassembly

Inspection and Repair

Reassembly and Installation

Power Take-Off

Removal

Disassembly

Inspection and Repair

Reassembly

Installation

Section 7 – Final Drive and Brakes

Specifications

Final Drive

Removal

Disassembly

Differential Shaft

Rear Axles

Inspection and Repair

Reassembly

Rear Axles

Differential Shafts

Installation

Brakes

Removal

Inspection and Repair

Installation

Brake Adjustment

Section 8 – Hydraulic System

Specifications

General

Cleaning

Handling of O-Rings

Principles of Operation

Hand Control and Rockshaft at Rest,

Oil Circulating at Low Pressure

Hand Lever Moved to Lower Implement,

Showing Path of Oil to And from Rockshaft Piston

Hand Lever Moved to Raise Implement,

Showing Path of Oil to And from Rockshaft Piston

Removal

Disassembly

Touch-Control Pump

Cylinder Block

Inspection and Repair

Reassembly

Installation

Trouble Shooting Test Procedure

General

Procedure

Trouble Shooting Chart

Section 9 – Electrical

Specifications

Timing

Distributor

Dwell Angle

Magneto

Alternator

Generators

Voltage Regulators

Cranking Motor

Wiring Diagram

Here’s what you can typically expect to find in such a manual and why it is a valuable purchase:

Technical Specifications: Detailed specifications about the tractor’s engine, transmission, hydraulic system, electrical system, and other key components.

Maintenance Procedures: Scheduled maintenance tasks, including fluid changes, filter replacements, lubrication points, and overall inspection guidelines to keep the tractor in optimal condition.

Repair Procedures: Step-by-step instructions for diagnosing and repairing specific issues that may arise. This includes guidance on troubleshooting problems in the engine, transmission, brakes, steering, and other systems.

Adjustment Procedures: Instructions for making adjustments to various components to ensure proper operation. This may include adjustments to the clutch, brakes, steering, and other critical systems.

Electrical Diagrams: Wiring diagrams and electrical schematics to assist with troubleshooting and repairing electrical issues. This section is crucial for understanding the tractor’s electrical system.

Hydraulic System Information: Details about the tractor’s hydraulic system, including diagrams and procedures for maintenance and repair. This is essential for owners using hydraulic implements.

Special Tools and Equipment: Information about any special tools or equipment needed for specific maintenance or repair tasks. This section ensures that owners are adequately equipped to perform the necessary work.

A service manual provides a detailed understanding of the tractor’s systems and components, empowering owners to troubleshoot issues and make informed decisions about repairs.

Preserving Resale Value: A well-maintained tractor with a documented service history, often based on a service manual, can have a higher resale value. Prospective buyers appreciate the availability of detailed service records.

Safety and Reliability: Proper maintenance and repairs contribute to the tractor’s safety and reliability. A service manual guides owners in performing tasks that contribute to the overall longevity of the tractor. An International Harvester Cub / Cub Lo-Boy Tractor Service Manual is a valuable resource for owners who want to maintain, troubleshoot, and repair their tractors. It serves as a comprehensive guide, ensuring that owners have the necessary information and procedures to keep their tractors in excellent condition.

The International Harvester (IH) Cub and Cub Lo-Boy tractors are compact utility tractors that were manufactured by International Harvester and later by Case IH.

Production Years: The Farmall Cub was produced from 1947 to 1979.

Engine: Typically equipped with a four-cylinder engine.

Features: The Farmall Cub was a small tractor designed for small farms and garden use. It featured a distinctive offset design, allowing it to straddle rows in fields.

International Harvester Cub Lo-Boy:

Production Years: The Cub Lo-Boy models were produced from 1955 to 1968.

Engine: Similar to the Farmall Cub, the Cub Lo-Boy had various engine options.

Features: The Lo-Boy models were designed with a lower profile, making them suitable for mowing and other applications where a lower center of gravity was beneficial.

Common Problems:

While the Cub and Cub Lo-Boy tractors are generally known for their durability and reliability, like any vintage equipment, they may experience certain issues due to age, wear, and maintenance. Some common problems reported by owners include:

Electrical Issues: Older tractors may have electrical problems, including issues with the ignition system, wiring, or lighting.

Engine Problems: Depending on the tractor’s age and maintenance history, engine-related issues such as oil leaks, worn-out components, or problems with carburetion may arise.

Transmission and Clutch: Some owners have reported issues with the transmission, such as difficulty shifting or problems with the clutch.

Hydraulic System: Leaks or malfunctions in the hydraulic system may occur, affecting the tractor’s ability to lift implements.

Steering and Front-end Issues: Wear in steering components or problems with the front-end alignment may be encountered.

PTO and Belt Issues: Problems with the power take-off (PTO) system or belt-driven accessories may need attention.

It’s important to note that many of these tractors are now considered vintage or antique, regular maintenance and inspections by a knowledgeable mechanic can help identify and address potential issues before they become major problems. A well-maintained and cared-for Cub or Cub Lo-Boy can provide many years of reliable service.

SKU: JS-IH-S-400

SKU: JS-IH-S-400 SKU: JS-IH-O-B

SKU: JS-IH-O-B SKU: IH-O-TD25C

SKU: IH-O-TD25C