Description

This John Deere 24 Series Balers Operators Manual is a reproduction of the original, out of print, John Deere 24 Series Balers Operators Manual. It provides you with everything you need to operate and service John Deere 24 Series Balers. The John Deere 24 Series Baler is a dependable machine. With proper care and operation, you

can expect to receive the service and long life designed and built into it. Like any precision machine your baler will require some attention at regular intervals. When any questions arise regarding lubrication and adjustments, etc., use your manual as a guide to service your machine the right way.

Issue H7

Table of Contents

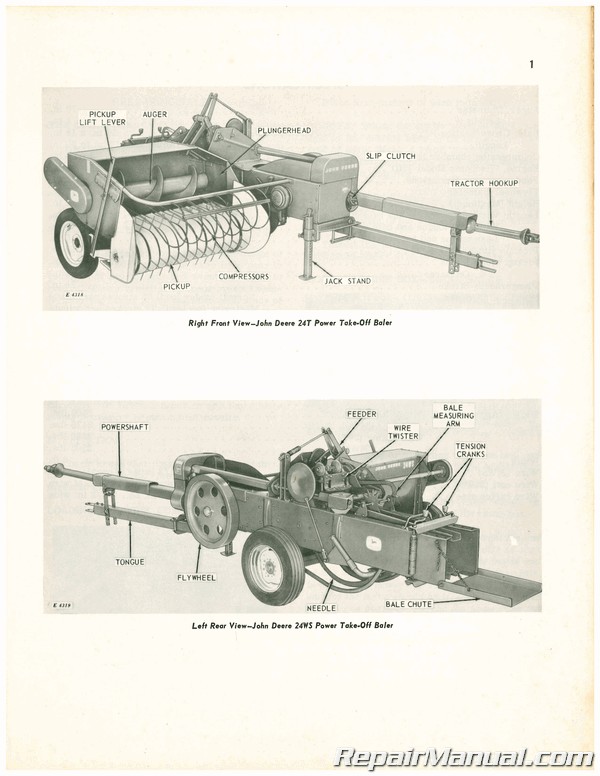

Identification views

Specifications

Operation

Lubrication

Trouble shooting

Service

Attachments

Assembly

Index of Topics

Assembly

Attachments

Auger drive belt

Auger drive gear case

Auxiliary feeder teeth

Bale chute

Bale counter

Bale ejector

Bale measuring control

Bale weight control

Belt, auger drive

Belt, engine

Belt tension, auger drive

Bevel gear and pinion adj (wire)

Billhook (twine)

Brake knotter drive

Breaking in baler

Bundles, shipping

Chain adjustments

Chain case, 1000 rpm

Clutch lever, engine

Clutch, slip

Compressors

Counter, bale

Crop preparation

Direction of travel

Drawbar

Dual wheels

Electric starting equipment

Engine

Engine and belt alignment

Feeder teeth, auxiliary

Feeder teeth, adjustment

Feeding difficulties

Field operation

Flail Shredder pickup

Flywheel shear bolt

Gear case

Gear case, auger drive

Gripper adjustment (wire)

Guide adjustment, plungerhead

Hitching to tractor

Hookup instructions

Hookup, tractor

How the knot is tied (twine)

How the wire is joined

Identification views

Implement operation

Intermittent gear adj (wire)

Jack stand

Knife adjustment, plungerhead

Knife arm (twine)

Knotter adjustments (twine)

Knotter and needle drive shear pin

Knotter difficulties (twine)

Knotter drive brake

Knotter gears (twine)

Lift lever, pickup

Loading twine box

Loading wire box

Lubrication

Main gear case

Measuring control, bale

Needle adjustment (twine)

Needle adjustment (wire)

Needle frame adjustment (twine)

Needle link adjustment (wire)

Needle shield

Needles, threading (twine)

Needles, threading (wire)

Operation

Overrunning clutch

Oversize tires

Pickup chain tension

Pickup compressors

Pickup balancing spring

Pickup difficulties

Pickup, flail shredder

Pickup gauge wheel

Pickup height

Pickup shear bolt

Pickup slip clutch

Pitman

Plungerhead and knife adjustment

Plungerhead extensions

Plungerhead guide adjustment

Plungerhead safety stop

Powershaft

Powershaft support brackets

Power take-off unit

Preparing implement

Rice standards, wheel adjusting

Safety slip clutch

Safety suggestions

Service

Service checking

Shear bolt, flywheel

Shear bolt, pickup

Shear pin, knotter and needle drive

Shield, needle

Shipping bundles

Side-drop bale chute

Slip clutch

Specifications

Spring, pickup balancing

Starting and driving

Storage

Threading needles (twine)

Threading needles (wire)

Timing haler

Timing feeder bearings

Timing marks

Timing needle lift shaft

Tongue height

Tongue position

Tool box

Transporting

Trouble shooting

Tucker fingers (twine)

Twine box

Twine disk

Twine holder

Twine tension

Twister difficulties (wire)

Twister hook adjustment (wire)

Universal joints

Wagon hitches and bale chute

Wheel adjusting rice standards

Wheel bearings

Wiper arm modeling tool (twine)

Wire box

Wire guide adjustments