Description

This 252 page, 1980-1983 Kawasaki KL250 Service Manual is a high quality reproduction of the original out of print manual. This manual provides detailed service information, step-by-step repair instruction and maintenance specifications for 1980-1983 Kawasaki KL250 dual sport motorcycles.

Table of Contents

Specifications – Engine Performance Curves, Running Performance Curves, Periodic Maintenance Chart

Adjustment – Engine – Spark Plug, Valve Clearance, Throttle Cable, Carburetor, Clutch, Engine Oil, Fuel System

Adjustment – Chassis – Front Fork, Rear Shock Absorbers, Drive Chain, Brakes, Brake Light Switch, Steering, Headlight, Horn, Lubrication

Disassembly – Introduction – Introduction To Disassembly, Torque And Locking Agent

Disassembly – Engine Installed – Flowchart, Air Cleaner Element, Fuel Tank, Ignition Coil, Cdi Unit, Muffler, Carburetor, Top End, Camshaft Chain Tensioner, Camshaft Sprocket, Camshaft, Rocker Arm, Cylinder Head, Valve, Valve Guide, Cylinder Block, Piston, Piston Rings, Left Side, Engine Sprocket, Clutch Release, Left Engine Cover, Magneto Flywheel, Magneto Stator, Neutral Switch, Camshaft Chain, Pick-up Coil, Right Side, Right Engine Cover, Bypass Valve, Engine Oil Pump, Oil Screen, Clutch, Primary Gear, Oil Pump Drive Gear , Kickstarter

Disassembly – Engine Removed – Flow Charts, Engine Removal, Crankcase Splitting, Transmission, Crankshaft, Crankcase

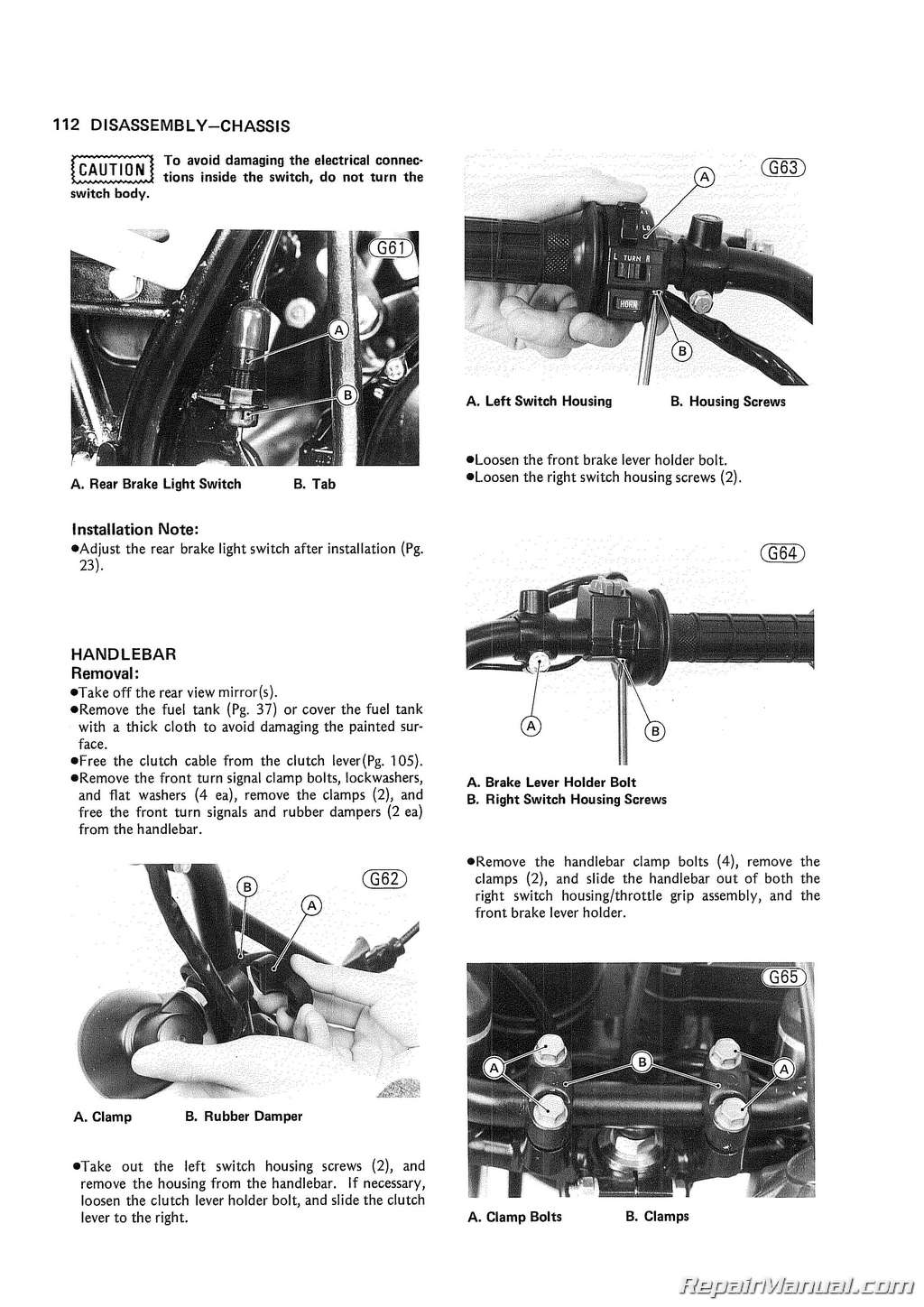

Disassembly – Chassis – Flow Chart, Wheels And Brakes, Front Wheel, Front Brake, Drive Chain, Rear Wheel, Rear Brake, Tire, Tube, Rim, Spoke, Cables, Front Brake, Clutch, Throttle, Speedometer, Tachometer, Lights, Headlights Unit, Speedometer, Meter Light, Tachometer, Meter Light, Indicator Lights, Indicator Lights (us And Canadian Models), Turn Signal Light, Turn Signal Assembly, Tail/brake Light, Switches, Ignition, Front Brake Light, Rear Brake Light, Steering, Handlebar, Steering Stem, Steering Stem Bearings, Suspension, Front Fork, Swing Arm

Maintenance – Engine – Engine Perspective, Air Cleaner, Carburetor, Camshaft, Camshaft Chain, Guides, Tensioner, Rocker Arms, Shafts, Cylinder Head, Valves, Cylinder Block, Piston, Crankshaft, Connecting Rod, Clutch, Transmission, Kickstarter, Engine Lubrication, Ball, Roller, Needle Bearings, Oil Seals, Muffler

Maintenance – Chassis – Fuel Tank, Fuel Tap , Wheels, Drive Chain, Sprockets, Brakes, Steering Stem, Front Fork, Rear Shock Absorbers, Swing Arm

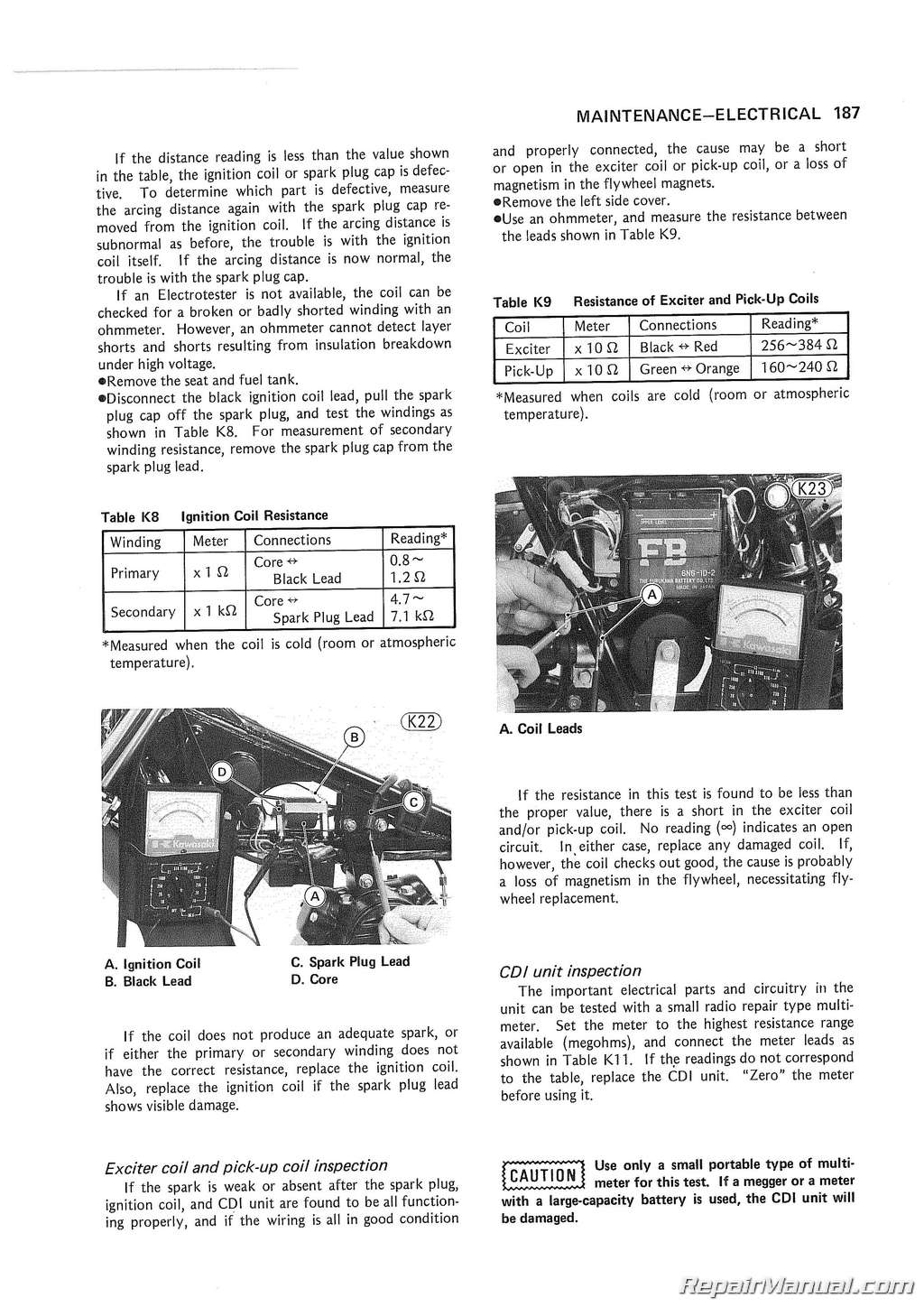

Maintenance – Electrical – Battery, Charging System, Ignition System, Ignition Switch, Neutral Switch, Lighting System, Horn, Speedometer, Tachometer

Troubleshooting Guide

Appendix – Additional Considerations For Racing, Special Tools

Includes Color Wiring Diagrams

This manual includes a supplement for 1983 Kawasaki KL250 motorcycles in the back.

Sample content from this 1980-1983 Kawasaki KL250 Motorcycle Service Manual:

The lower part of the jet needle is tapered and extends down into the needle jet. It is fixed to the vacuum piston, and thus rises up in the needle jet as the vacuum piston rises. From the time the vacuum piston starts rising, about 1/4 throttle, until it reaches most of the way up in the carburetor bore, the fuel is metered primarily by the jet needle taper. As the jet needle rises, the needle-to-jet clearance increases, thereby increasing the amount of fuel that can pass up through the jet. The vacuum piston is attached to the diaphragm and rises only between 1/4 and 3/4 throttle. Through the hole in the bottom of the piston, the air pressure In the bottom of the piston, the air pressure in the chamber above the diaphragm is reduced by engine intake vacuum. The air vent maintains atmospheric pressure in the chamber under the diaphragm. As engine speed increases, air pressure in the upper chamber decreases. The difference between this pressure and atmospheric pressure in the lower chamber becomes greater. The force of the spring and the weight of the piston are overcome, and the piston rises to an extent corresponding to this pressure difference. The diaphragm is made of rubber and absorbs the vibration caused by engine intake pulsing to prevent the vacuum piston from wearing.