Description

This 305 page, Massey Ferguson MF200 & MF200B Crawler Service Manual is a reproduction of the original out of print manual. This manual provides detailed service information, step-by-step repair instruction and maintenance specifications for Massey Ferguson MF200 & MF200B Crawlers.

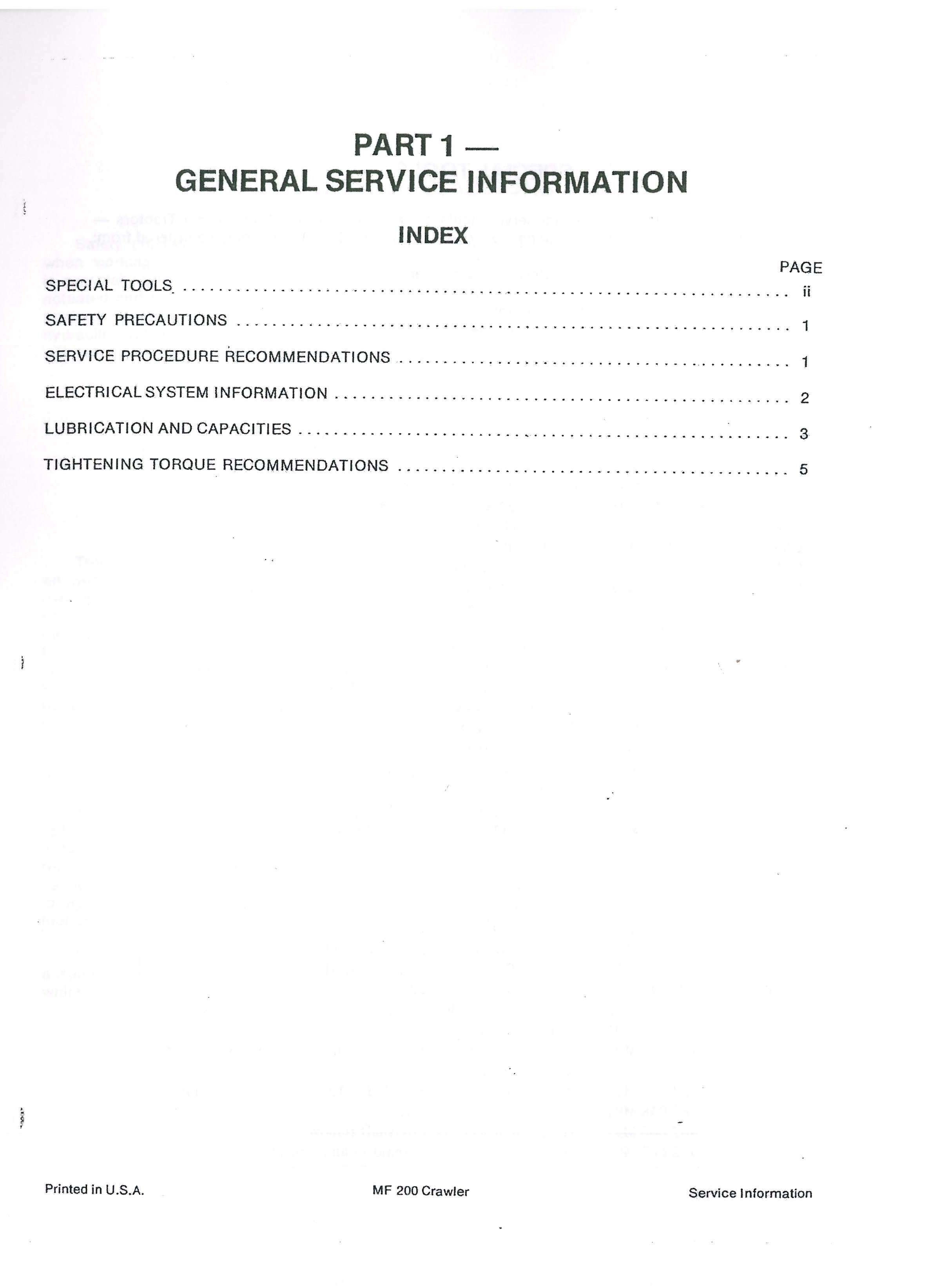

Table of Contents

General Service Information

Special Tools

Safety Precautions

Service Procedure Recommendations

Electrical System Information

Lubrication and Capacities

Tightening Torque Recommendations

Engine

Introduction

Engine Removal

Engine Installation

Cylinder Head

Valves

Valve Guides

Valve Seats

Valve Springs

Tappets

Cylinder Head Reassembly

Cylinder Head Installation

Adjusting Valve Tappet Clearance

Cylinder Block (stripped)

Piston and Connecting Rod Assembly

Cylinder Liners

Timing Gear Cover and Front Crankshaft Oil Seal

Timing Gears

Camshaft

Timing Gear Housing

Crankshaft and Main Bearings

Rear Crankshaft Oil Seal

Flywheel

Clutch

Removal and Disassembly

Inspection and Repair

Reassembly and Installation

Clutch Adjustments

Clutch Release Levers

Clutch Pedal Free Travel

Technical Data

Manual Shuttle Transmission, Ring Gear & Pinion (includes 4-Speed Sliding Gear Transmission)

Description and Operation

Transmission Brake

Manual Shuttle Transmission

Splitting (clutch/transmission Housing)

Reconnecting

Disassembly and Removal

Inspection

Reassembly and Installation

Four-Speed Transmission

Disassembly

Inspection

Reassembly

Ring Gear and Pinion

Removal

Installation and Adjustments

Hydraulic Coupling

Description

Lubrication Specifications

Servicing and Repair

Removing Cover Bearing and Oil Seal

Replacing Oil Seals

Assembling Turbine and Cover

Servicing Flywheel

Installing a New Flywheel

Assembling Hydraulic Coupling

Hydraulic Reverser Transmission, Ring Gear and Pinion

Specifications

Description

Hydraulic Circuit Description

Hydraulic Reverser Transmission

Removal

Installation

Disassembly

Reassembly

Reverserclutch

Disassembly

Piston

Disassembly

Inspection

Reassembly

Reassembly

Oil Distributor

Disassembly

Reassembly

Clutch (inching or Pause) Pedal Housing

Disassembly ’

Reassembly

Transmission Test Procedure

Testing Hydraulic Pump

Testing Main Relief Valve Pressure

Checking Clutch Working Pressure

Restrictor Valve Setting

Trouble-Shooting Chart

Hydraulic Pump

Description

Removal and Installation

Disassembly

Reassembly

Steering Clutches And Brakes

Description and Operation

Adjustments

Steering Clutches and Brakes

Brake Band Adjustment

Brake Pedal Free Travel Adjustment

Steering Lever Free Travel Adjustment

Steering Clutches

Replacement of Clutch Plates and Discs

Removal of Clutch Assembly

Inspection

Reinstalling

Steering Brakes

Brake Drums

Brake Bands

Clutch Release Bearings

Replacement

Specifications

Final Drives

Description

Removal

Installation

Disassembly

Reassembly

Suspension and Tracks

Description

Tracks

Removing the Tracks

Inspection and Checks

Installing the Tracks

Disassembling the Tracks

Reassembling the Tracks

Track Roller Frame

Removal and Installation

Rear Cross Bar

Removing Cross Bar

Installing Cross Bar

Front Beam

Removing Front Beam

Installing Front Beam

Sprocket Wheel

Removal and Installation

Idler Wheel

Removal and Installation

Disassembly

Reassembly

Track Carrier Rollers

Removal and Installation

Disassembly

Reassembly

Track Rollers

Removal and Installation

Disassembly and Reassembly

Specifications

Electrical Systems

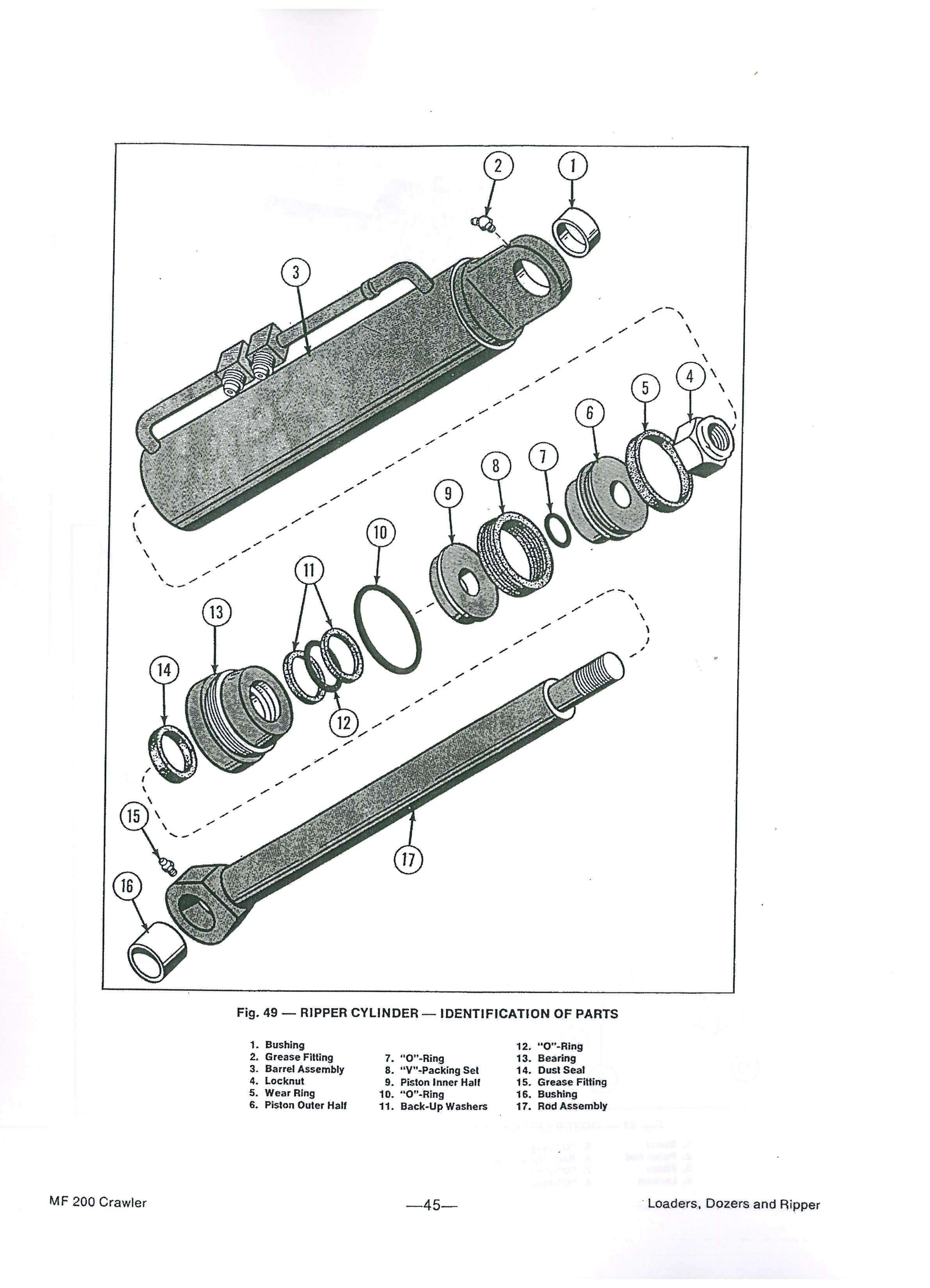

Loaders, Dozers and Ripper

Safety Precautions

Service Information

Understanding the Hydraulic Systems

Loaders

Dozers

Ripper

Tests and Adjustments

Checking System Main Pressure

Testing and Adjusting Circuit Relief Within 3-Spool Valve

Testing for Valve Spool Leakage and Checking Spool Travel

Testing “load Checks”

Checking Pump Efficiency (gpm)

Testing for Internal Cylinder Leakage

Testing and Adjusting Clam Cylinder Circuit Relief

Troubleshooting

Reservoir

Filter and By-Pass Poppet

Hydraulic Pump

3-Spool Control Valve

1-Spool Control Valve

Cylinders

Backhoe

Safety Precautions

Service Information

Understanding the Hydraulic System

Tests and Adjustments

Operational Check of Backhoe

Operational Check of Swing

Checking System Main Pressure

Testing Circuit Reliefs

Adjusting Circuit Reliefs

Testing “load Checks”

Testing for Valve Spool Leakage and Checking Spool Travel

Testing for Internal Cylinder Leakage

Trouble-Shooting

Control Valve

Cylinders — Double-Acting

Rotary Cylinder

Winch

Brake Assembly

Brake Adjustment

Clutch Assembly

Clutch Adjustment

Drum Assembly

Ring Gear and Pinion Assembly

Ring Gear and Pinion Adjustment

Master Control

Bleeding Hydraulic System

Trouble-Shooting

Power Take-Off

Servicing

Removal

Installation

Disassembly

Reassembly