Description

This 124 page, PD-4106 GM Bus Supplement Service Manual is a high quality reproduction of the original out of print publication. It was originally published in 1964. This manual provides detailed service information, step-by-step repair instruction and maintenance specifications for Model PD-4106 GM Buses.

The information contained in this supplement, when used in conjunction with Maintenance Manual X-6114, provides all the procedures and data required to adequately service the latest Coach Model PD-4106. Since all the equipment covered in this supplement was not introduced in production usage simultaneously, it will be necessary to inspect the units being serviced on each individual coach to determine whether coverage is made in this supplement or in the previous manual. The information in this supplement is arranged in the same sequence and under the same section headings as in Manual X-6114. This information covers the units and systems in which there have been major changes since Maintenance Manual X-6114 was published. Refer to the applicable section in this supplement first, to determine whether there is supplementary information before servicing any unit or system on these coaches. If there is none, then service unit or system in accordance with Maintenance Manual X-6114.

Table of Contents

Heating System

Lavatory

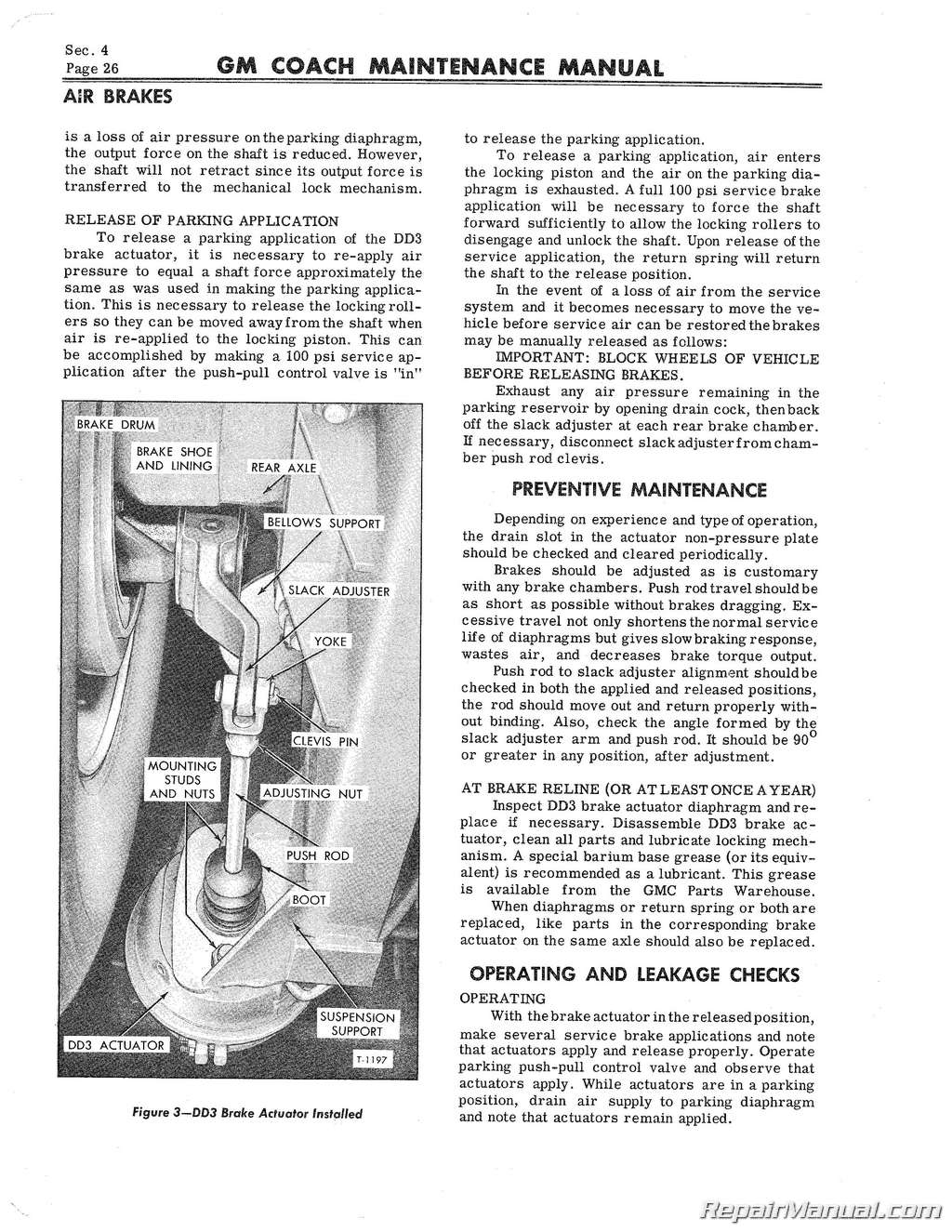

Dd3 Brake Actuator System

Clutch And Controls

Electrical System

Height Control Valves

Power Steering

Air Conditioning

Wiring Diagrams

Index of Topics

Actuator, DD3 Brake

Maintenance

Replacement

Tests

Air Conditioning

Lubrication and Inspection

System Services and Tests

Air Suspension

Blower, Lavatory Ventilator

Motor Replacement

Buzzer, Lavatory Emergency

Clutch and Controls

Adjustments

Assist Mechanism Replacement

Maintenance

Removal and Overhaul

Clutch, Refrigerant Compressor Drive

Compressor, Refrigerant

Replacement and Alignment

Coupling, Compressor Mounting and Drive

DD3 Brake System

Electrical System

Breakers, Driver’s Control Panel Circuit

Breakers, Electrical Compartment

Circuit

Connectors, Amphenol

Diagrams, Electrical Circuit

Generator

Junctions, Driver’s Control Panel

Junctions, Electrical Compartment Panel

Lighting System

Regulator

Adjustment

Troubleshooting

Relays

Shut-off, Automatic Engine – –

Starting System

Fan and Drive, Condenser

Overhaul

Replacement

Faucet, Wash Basin Water

Grad-U-Stat

Shop Test

Test and Adjustment (In Coach)

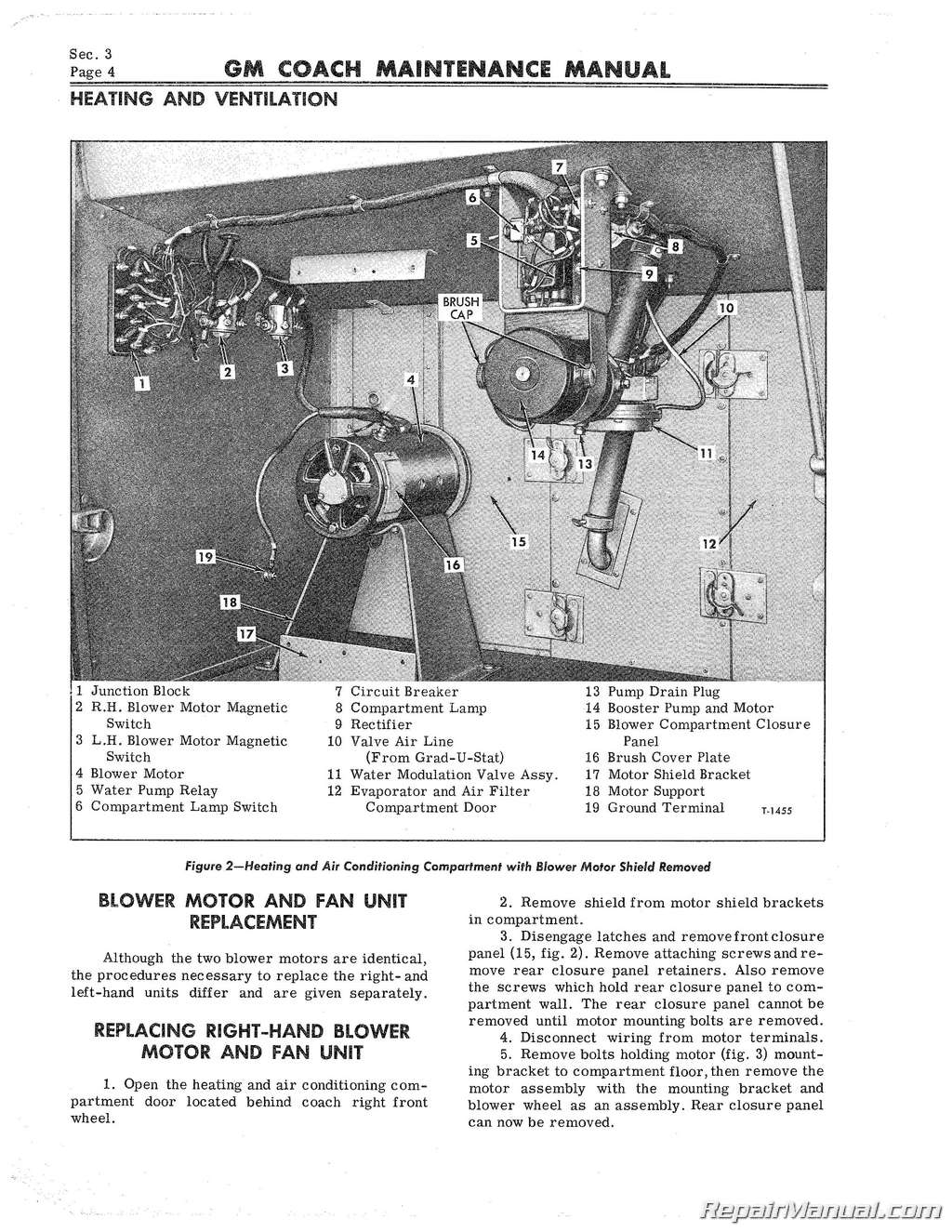

Heating and Ventilation

Lavatory

Draining System

Maintenance

Light, Lavatory Dome

Lock, Lavatory Door

Motor, Blower

Brushes, Replace

Inspection and Test

Maintenance

Overhaul

Replace LH

Replace RH

Speed Check

Motor, Condenser Fan Drive

Pump, Heater Water

Refrigerant

Relay, Lavatory Blower

Relay, Lavatory Control

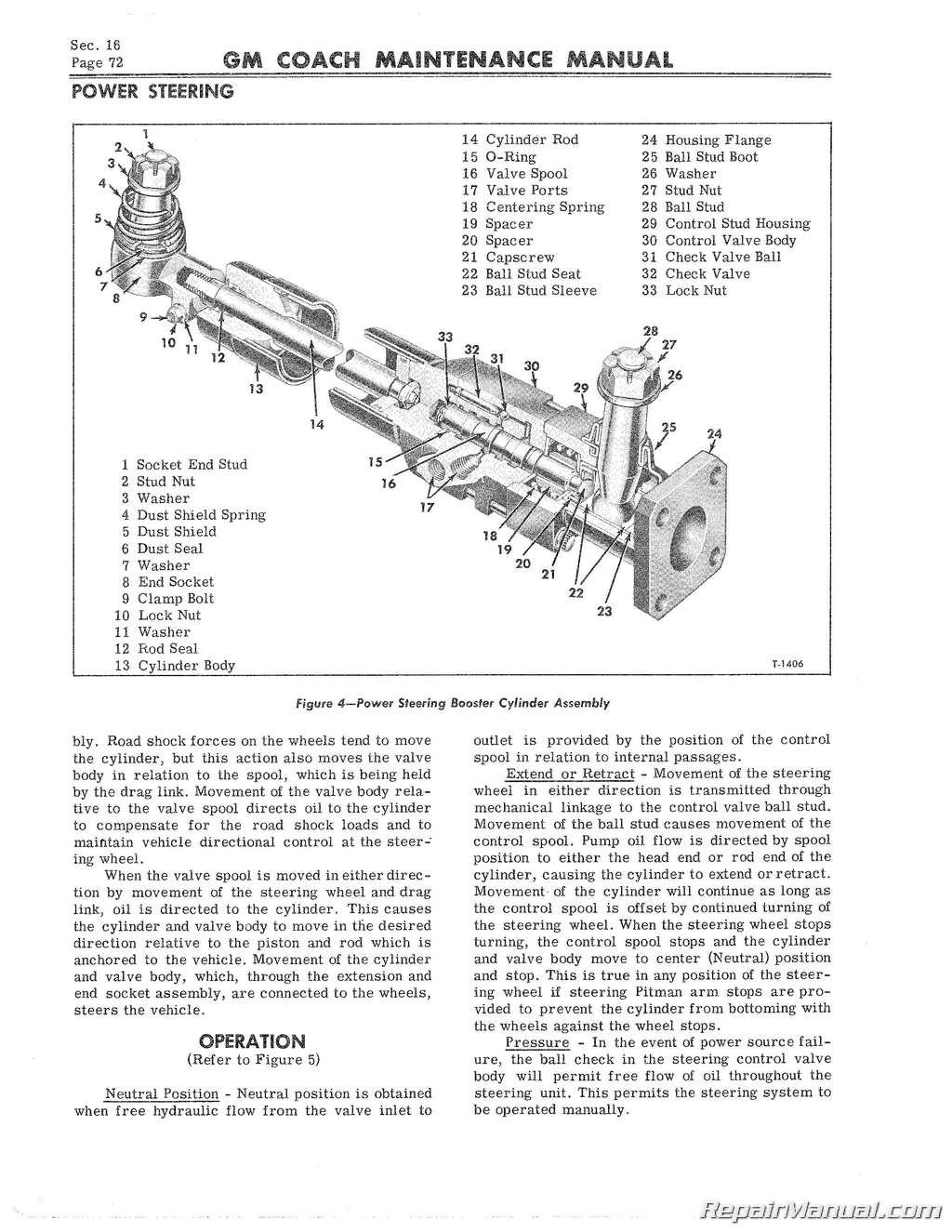

Steering, Power

Bleeding System

Booster Cylinder

Steering, Power (Cont’d)

Booster Cylinder

Operation

Overhaul

Replacement

Troubleshooting

Drag Link

Filter, Fluid Line

Maintenance

Operation

Pressure Test

Pump, Hydraulic

Operation

Overhaul

Replacement

Troubleshooting

Reservoir, Fluid

Sockets, End and Extension

Strainer, Refrigerant Dehydrator

Switch, Emergency Buzzer

Switch, Lavatory Door Lock

Tank, Lavatory Chemical

Tank, Wash Basin Supply

Tank, Wash Basin Waste

Valve, Expansion

Valve, Height Control

Adjustments

Operation

Overhaul

Replacement

Tests

Troubleshooting

Valve, Inversion

Maintenance

Operation

Replacement

Tests

Valve, Push-Pull Control

Replacement

Valve, Wash Basin Check

SKU: X-6034

SKU: X-6034 SKU: X-6733

SKU: X-6733 SKU: X-7430A

SKU: X-7430A