Description

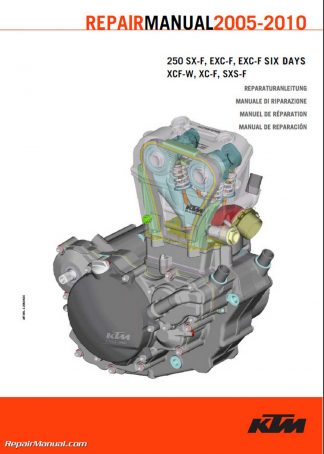

This 2005-2010 KTM 250SX-F Engine Repair Manual is an authorized reproduction of the original, out of print manual. It covers ONLY the engine on the following motorcycle models:

2005, 2006, 2007, 2008, 2009, 2010 KTM 250SX-F Racing 4 Strokes

This is a printed and bound 125 page paper manual. (3206063-E)

This engine service manual contains the following information:

GENERAL INFORMATION – BLEEDING THE COOLING SYSTEM, CHANGING THE OIL FILTER, OIL CIRCUIT, BLEEDING OF THE HYDRAULIC CLUTCH, ADJUSTING THE THROTTLE CABLES, SPECIAL TOOLS ENGINE

REMOVING AND REFITTING ENGINE – DISMOUNTING THE ENGINE, MOUNTING THE ENGINE

DISASSEMBLING ENGINE – PREPARATORY WORK, MOVING THE ENGINE INTO THE TDC POSITION, REMOVING THE CAMSHAFTS, REMOVING THE CYLINDER HEAD AND PISTON, REMOVING THE CLUTCH COVER, DISMANTLING THE CLUTCH, REMOVING THE CHAIN DRIVE AND PRIMARY GEAR, DISMANTLING THE SHIFT MECHANISM, REMOVING THE OIL PUMPS, SEPARATING THE CASING HALVES, REMOVING THE CRANKSHAFT AND TRANSMISSION SHAFTS

SERVICING INDIVIDUAL COMPONENTS – LEFT CASING HALF, RIGHT CASING HALF, BYPASS VALVE, CLUTCH COVER, CRANKSHAFT, MEASURING THE OUTSIDE DIMENSION OF THE CRANKSHAFT WEBS, CRANKSHAFT BEARINGS, AXIAL CLEARANCE OF THE CRANKSHAFT, CYLINDER, MEASURING THE PISTON AND CYLINDER, MOUNTING CLEARANCE, PISTON, PISTON RING END GAP, CHECKING THE OIL PUMPS FOR WEAR, LUBRICATING SYSTEM, CAMSHAFT BEARING, CAMSHAFTS, AUTOMATIC DECOMPRESSION, CAMSHAFT BEARING BRIDGES, TIMING CHAIN TENSIONER, TIMING CHAIN, CYLINDER HEAD, CLUTCH, KICKSTARTER, PRE-MOUNTING THE KICKSTARTER SHAFT, SHIFT MECHANISM, PRE-MOUNTING THE SHIFT SHAFT, GENERAL INFORMATION ON SERVICING THE TRANSMISSION, ASSEMBLING THE MAIN SHAFT, ASSEMBLING THE COUNTERSHAFT

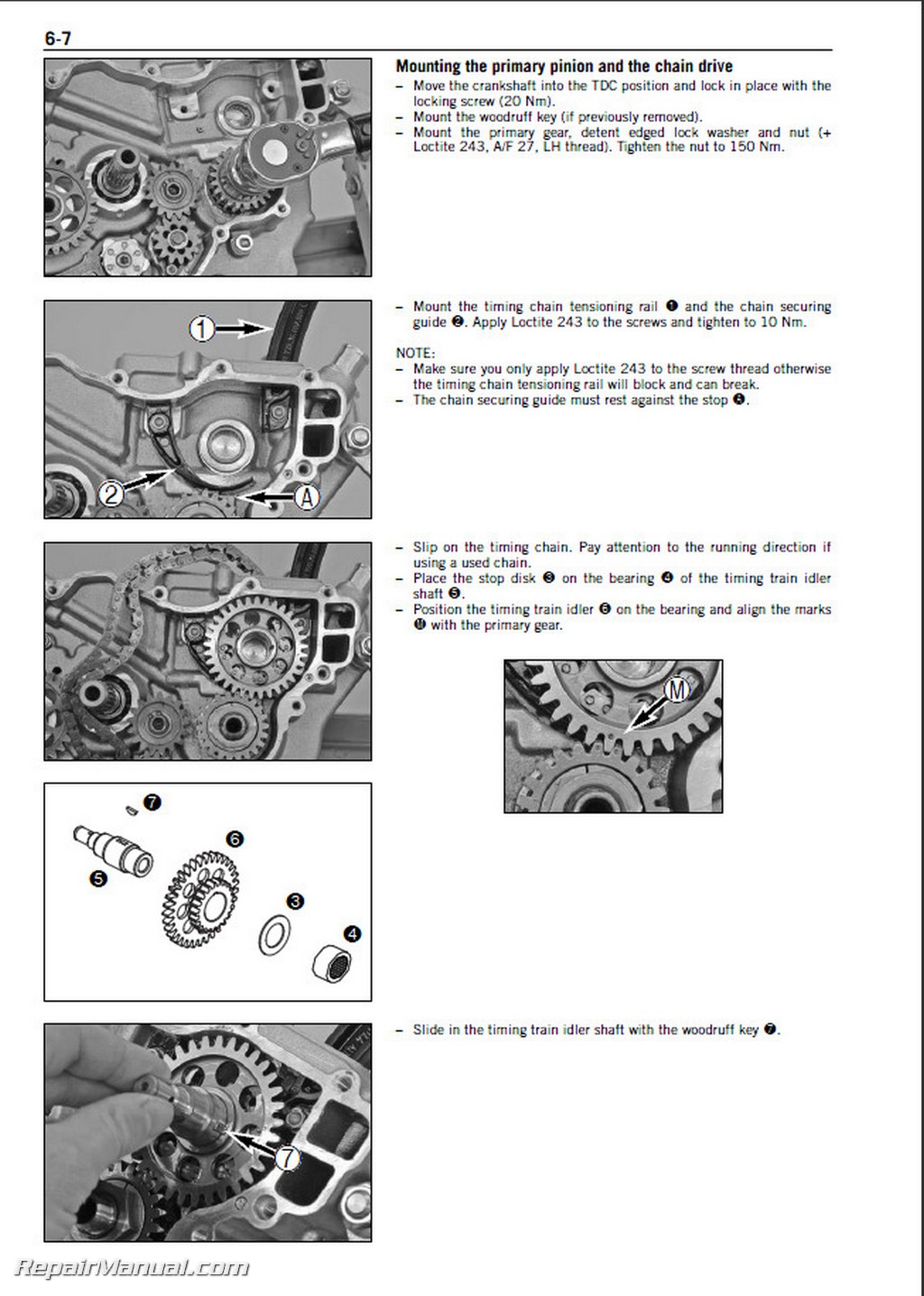

ASSEMBLING ENGINE – INSTALLING THE TRANSMISSION SHAFTS AND CRANKSHAFT, ASSEMBLING THE CASING HALVES, MOUNTING THE OIL PUMPS, MOUNTING THE SHIFT MECHANISM, MOUNTING THE PRIMARY PINION AND THE CHAIN DRIVE, MOUNTING THE CLUTCH, MOUNTING THE CLUTCH COVER, MOUNTING THE PISTON AND CYLINDER HEAD, MOUNTING THE CAMSHAFTS, MOUNTING THE CHAIN TENSIONER, CHECKING THE VALVE CLEARANCE, ASSEMBLING THE ENGINE

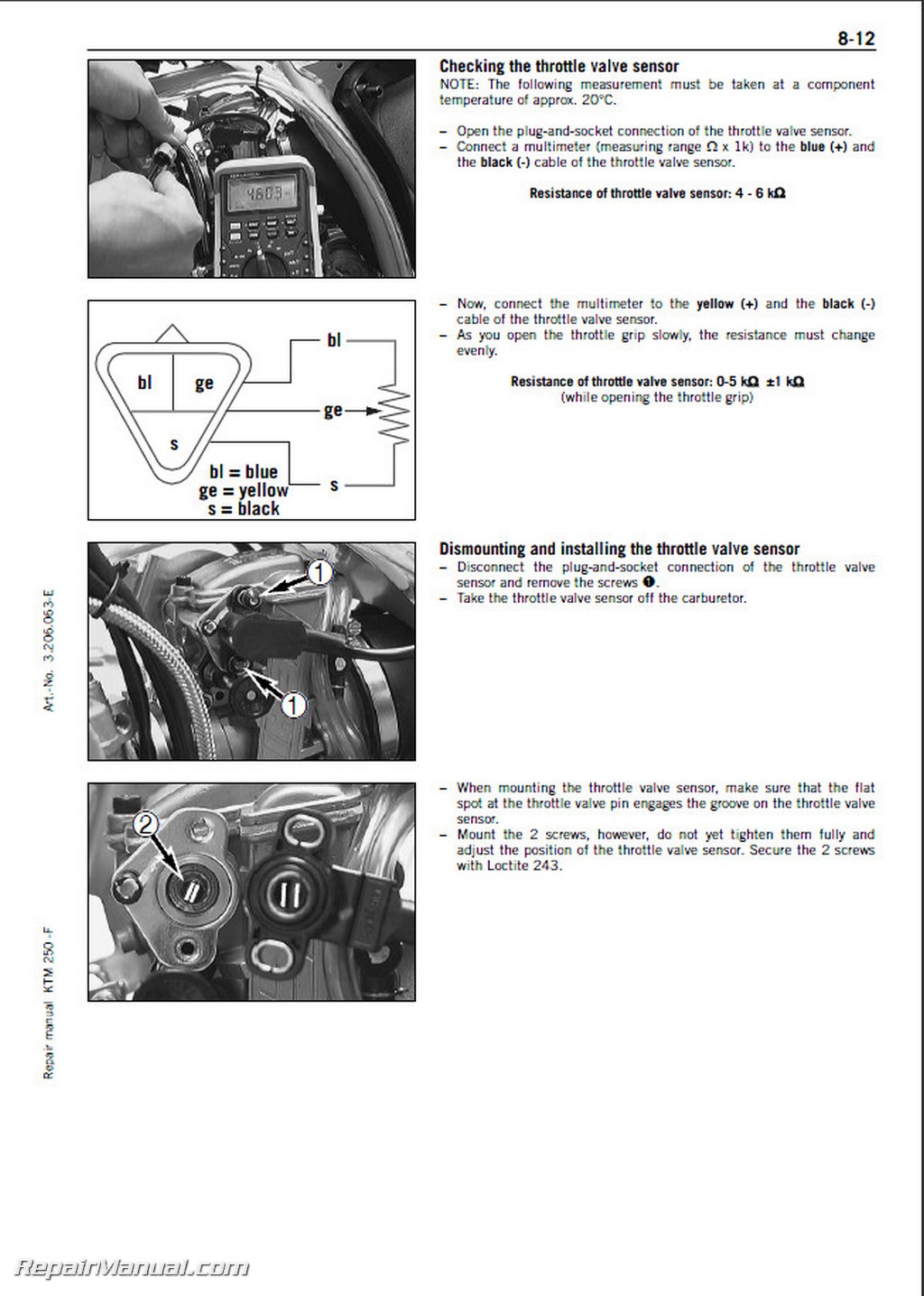

ELECTRICAL – CDI UNIT, CHECKING THE IGNITION COIL, TROUBLESHOOTING IN THE IGNITION SYSTEM, IGNITION SYSTEM, CHECKING THE STATOR AND PULSE GENERATOR REPLACING THE STATOR, MEASURING WITH THE PEAK VOLTAGE ADAPTER STATIC IGNITION VALUES, THROTTLE VALVE SENSOR,ADJUSTING & CHECKING

FUEL SYSTEM – DISMOUNTING AND INSTALLING THE CARBURETOR, DISASSEMBLING THE CARBURETOR, CHOKE KNOB AND HOT START SLIDE, CHECKING THE ACCELERATOR PUMP, CHECKING THE JET NEEDLE, CHECKING THE FLOAT NEEDLE VALVE, CHECKING THE THROTTLE VALVE, ASSEMBLING THE CARBURETOR, ADJUSTING THE POSITION OF THE THROTTLE VALVE SENSOR, CHECKING THE THROTTLE VALVE SENSOR, DISMOUNTING AND INSTALLING THE THROTTLE VALVE SENSOR, CARBURETOR ADJUSTING IDLING, CHECKING/ADJUSTING THE FLOAT HEIGHT

TROUBLE SHOOTING

TECHNICAL SPECIFICATIONS – ENGINE, CHASSIS, MOUNTING CLEARANCES, WEAR LIMITS, TIGHTENING TORQUES, ENGINE, CHASSIS

PERIODIC MAINTENANCE SCHEDULE

WIRING DIAGRAMS