Description

This 230 page, Satoh S650G Factory Tractor Service Manual provides detailed service information, step-by-step repair instruction and maintenance specifications for Satoh S650G models. This reproduction manual is a copy of the original out of print factory manual.

Satoh S650G Service Manual Model Coverage

Satoh S650G Tractors

Satoh S650G Service Manual Table of Contents

THE ENGINE – GENERAL

1. Cylinder Head.

2. Cylinder Block

3. Pistons and Crankshaft

4. Valve Mechanism

5. Intake and Exhaust Mechanism

6. Governor

7. Cooling System

8. Lubricating Mechanism

9. Electrical System

ENGINE

1. Disassembling Order

1-1. Removing the Engine.

1-2. Disassembling the Engine

2. Checking Maintenance and Limit of Adjustment

2-1. Cylinder Head

2-2. Piston and Cylinder Block.

2-3. Connecting Rod

2-4. Crankshaft and Main Bearing Metal.

2-5. Camshaft

2-6. Timing Chain Sprocket and Chain Adjuster

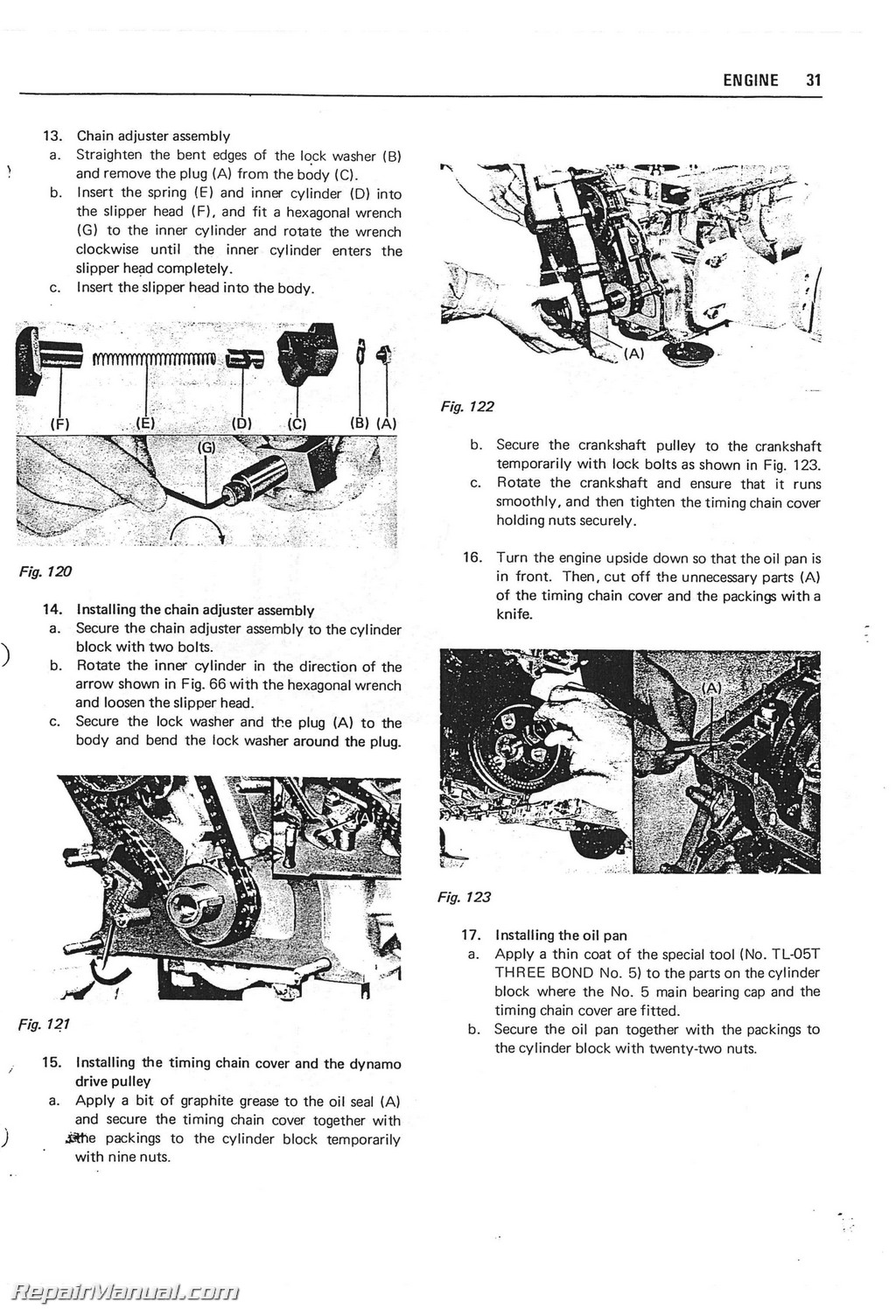

3. Assembling Order

3-1. Assembling the Engine

3-2. Mounting the Engine

4. Specifications

LUBRICATION SYSTEM

1. Lubrication System – General

2. Disassembling the Oil Pump

2-1. Removing the Oil Pump

2-2. Disassembling the Oil Pump

3. Checking, Maintenance and Limit of Adjustment

3-1. Checking and Adjusting the Oil Pump

3-2. Oil Filter Replacement.

3-3. Checking and Adjusting the Oil Pump Driven Gear Shaft

3-4. Adjusting the End Play of Oil Pump Driven Gear Shaft

4. Assembling Order

4-1. Assembling the Oil Pump

4-2. Mounting the Oil Pump

5. Specifications

5-1. Oil Pump Specifications

5-2. Oil Filter Specifications

COOLING SYSTEM.

1. Cooling System – General

2. Disassembling Order

2-1. Removing the Water Pump.

2-2. Disassembling the Water Pump

3. Checking Maintenance and Limit of Adjustment

3-1. Inspection of Water Pump

3-2. Checking the Thermostat

4. Assembling the Water Pump

5. Mounting the Water Pump

6. Installing the Thermostat

7. Specifications

7-1. Water Pump

7-2. Thermostat

FUEL SYSTEM

1. Fuel System – General

2. Air Cleaner.

2-1. Removing the Air Cleaner Element

2-2. Checking the Air Cleaner

2-3. Air Cleaner Specifications

3. Fuel Pump.

3-1. Removing the Fuel Pump

3-2. Disassembling the Fuel Pump

3-3. Checking the Fuel Pump

3-4. Assembling the Fuel Pump

3-5. Installing the Fuel Pump

3-6. Fuel Pump Specifications

4. Fuel Filter.

5. Carburetor

5-1. Construction

5-2. Disassembling the Carburetor

5-3. Checking, Maintenance and Limit of Adjustment

5-4. Assembling the Carburetor

5-5. Mounting the Carburetor

5-6. Specifications

6. Governor

6*1. Governor System – General

6-2. Governor – Operation and Construction

6-3. Purpose of Governor Adjustments

6-4. Maintenance

6-5. Interlock Adjustment between Carburetor and Governor

IGNITION SYSTEM

1. Spark Plug

1-1. Inspection and Adjustment of Spark Plug

1-2. Spark Plug Specifications

2. Distributor

2-1. Removing the Distributor

2-2. Disassembling the Distributor

2-3. Checking, Maintenance and Limit of Adjustment

2-4. Assembling the Distributor

2-5. Mounting the Distributor

2-6. Ignition Timing Inspection and Adjustment

2-7. Distributor Specifications

TROURLESHOOTING

1. The Engine Lacks Power

1-1. Fuel Compression is Insufficient

1-2. Ignition Timing is Incorrect

1-3. Fuel Level is Low

1-4. Carburetor Draws Insufficient Amount of Air

1-5. Engine Overheats

2. Fuel Cansumption is Excessive

2-1. Engine Oil Leaks

2-2. Oil Comes Up into the Combustion Chamber

2-3. Oil Comes Down from Valve System

3. Engine is Hard to Start.

3-1. Engine has Starting Difficulty

3-2. Ignition System is Defective

3-3. Engine

3-4. Carburetor

4. Engine is Noisy

4-1. Piston

4-2. Crankshaft

4-3. Connecting Rod

4-4. Miscellaneous

5. Firing Irregularities

5-1. Ignition System

5-2. Air-fuel Mixture

5-3. Valves

5-4. Cylinder Head

6. Incorrect Idle Speed Adjustment

6-1. Carburetor

6-2. Air Entering Fuel Line

6-3. Valves

6-4. Cylinder Head

7. Engine Runs not Smoothly (when accelerated)

7-1. Carburetor

7-2. Ignition System

7-3. Engine

CLUTCH SYSTEM

1. General

2. Construction

3. Disassembling Order

3-1. Disassembling Order Using A Method

3-2. Clutch Assembly Disassembling Order.

3-3. Disassembling Order Using B Method

3-4. Clutch Pedal Mechanism Disassembling

4. Assembling (Adjusting) Order

4-1. Clutch Pedal Mechanism Assembling

4-2. Clutch Assembly Assembling and Fitting

4-3. Overall Assembling

5. Inspection, Maintenance and Limit of Modification

6. Troubleshooting

6-1. Clutch Slips

6-2. Clutch Drag

6-3. Shudder when Starting.

6-4. Clutch Overheat

7. Specifications

STEERING LINKAGE SYSTEM

1. General

Front Axle and Steering Assembly

2. Explanation of Construction.

3. Disassembling Order

3-1. Disassembling the Entire Front Axle

3-2. Disassembling King Pin and Front Hub.

4. Assembling (Adjusting) Order

4-1. Assembling Related Parts for King Pin and Front Hub

4-2. Assembling of Entire Front Axle

5. Disassembling Order

5-1. Disassembling Order of Steering

6. Assembling (Adjusting) Order

6-1. Assembling (Adjusting) Order of Steering.

7. Method of Inspection, Adjustment, and Limit of Repair

8. Troubleshooting

8-1. Front Wheel Shimmy

8-2. Hard Steering

8-3. Pull to One Side.

8-4. Excessive Play on Handle

9. Specifications

TRANSMISSION SYSTEM

1. General

2. Construction.

3. Disassembly

3-1. Transmission Removal

3-2. Transmission Disassembly

3-3. Power Transmission Disassembly

3-4. Power Take Off Disassembly

3-5. Differential Unit Disassembly

3-6. Final Drive Disassembly

3-7. Piston Shaft Disassembly

4. Assembling (Adjustment)

4-1. Power Transmission Assembly

4-2. Range Shaft Assembly

4-3. Selecter Unit Assembly

4-4. P.T.O. Assembly

4-5. Differential Gear Assembly

4-6. One-way Clutch Assembly

4-7. Final Drive Assembly

4-8. Differential Lock Assembly

4-9. Final Drive Case Fitting

4-10. Transmission Fitting

5. Dimensional Date

5-1. Bolt and Nut Tightening Torques

5-2. End Float

5-3. Backlash

5-4. Gear Vibration.

5-5. Others

BRAKE SYSTEM

1. General

2. Operation

3. Disassembling Order

3-1. Brake Drum Disassembling Order

3-2. Brake Pedal Disassembling Order

4. Assembling (Adjusting) Order

4-1. Brake Drum

4-2. Brake Pedal

4-3. Adjustment after Assembling

5. Inspection, Maintenance and Limi: of Modification

6. Troubleshooting

6-1. Brake Insufficient

6-2. Brake Remain ON

6-3. Strange Sound Heard

7. Specifications

HYDRAULIC SYSTEM

1. General

2. Construction

2-1. Height Control System

2-2. Neutral Position

2-3. Lifting Position

2-4. Lowering Position

2-5. Floating Position.

2-6. Control Lever and Link System

3. Disassembling Order

3-1. Hydraulic System – Removal and Disassembly

3-2. Control Valve – Removal and Disassembly

3-3. Lock Valve – Disassembly

4. Assembling (Adjusting) Order

4-1. Lock Valve – Assembly

4-2. Control Valve (Whole Part) – Assembly

4-3. Hydraulic System – Assembly

4-4. Adjustments

5. Oil Pump

5-1. Oil Pump – Construction.

5-2. Oil Pump Disassembling Order

5-3. Oil Pump – Disassembly

5-4. Checking During Disassembling.

5-5. Oil Pump Assembly Order.

5-6. Oil Pump – Installation and Trial Run

6. Sub-Control Valve – Description

6-1. Installation

6-2. Neutral Position

6-3. Lifting Position

6-4. Lowering Position

6-5. Sub-Control Valve – Disassembly

6-6. Checking During Disassembling

6-7. Sub-Control Valve – Assembly

Troubleshooting

7-1. With Control Lever in the lifting position,

implement will not move up

7-2. With Control Lever in neutral, implement will show

hunching or lowering from the lifted position

7-3. Lifting Speed is slow

(Engine Speed 2,800 rpm/min @1,110 lb (500 kg) @1,2 sec.)

7-4. With Control Lever in the lowering position,

implement will not lower

7-5. Control Valve Lever will not move upward

7-6. Oil Temperature is too high

7-7. Informal noise.

7-8. With Sub-Control Lever in the lifting position,

implement will not move upward

7-9. Lifting speed is slow

7-10. With Sub-Control Lever in neutral.

implement with load will lower

7-11. Sub-Control Lever will not automatically return to neutral

Specifications

ELECTRICAL SYSTEM

1. General

2. Wiring Diagram

3. Battery

3-1. Dry Charge.

3-2. Initial Charging.

3-3. Auxiliary Charging

3-4. Handling and Inspection

3-5. Specifications

4. Alternator and Regulator

4-1. Notes on Alternator.

4-2. Removing the Alternator

4-3. Inspecting the Alternator

4-4. Installing the Alternator

4-5. Inspecting the Charging System

4-6. Inspecting the Regulator

4-7. Specifications

5. Starter.

5-1. Disassembling the Starter

52. Inspecting the Starter

53. Assembling the Starter

5-4. Testing the Starter

55. Specifications

6. Safety Switch

6-1. Adjustment.

DRAFT CONTROL

1. Outline of Construction

2. Setting the Draft Control in Place

3. Assembly

4. Fabrication of the Sensing Block

5. Marking

6. Adjustments of the Controls

6-1 Adjustment of the Height Control

6-2 Adjustment of the Draft Control

6-3 Adjustment of the Traction Control

6-4 Adjustment of the Sensing Units

7. Assembly and Disassembly

8. Operation

8-1 Explanation of Operation in Height Control (Position Control)

8-1-1 Neutral Position

8-1-2 Raise Position

8-1-3 Down Position

8-1-4 Floating Position

8-2 Explanation of Operation in Traction Control

8-3 Explanation of Operation in Draft Control

8-3-1 The Case of Operation to the Side of “Large” Tractive Force

8-3-2 The Case of Operation to the Side of “Small” Tractive Force

8-3-3 Operation of the Valve in Case Traction Resistance Fluctuates Under

the Fixed Condition of the Control Link (8) at an Optional Position

8-3-4 Operation of the Valve in Case Working Equipment is Operated for

the Maximum Lift Under the Condition of the Draft Control

9. Specifications

SKU: HO-P-H-30

SKU: HO-P-H-30 SKU: JS-GR-S-L-ERLY

SKU: JS-GR-S-L-ERLY SKU: JS-WI-S-VH4

SKU: JS-WI-S-VH4